Expansion Shell Anchor Bolt

Product Introduction

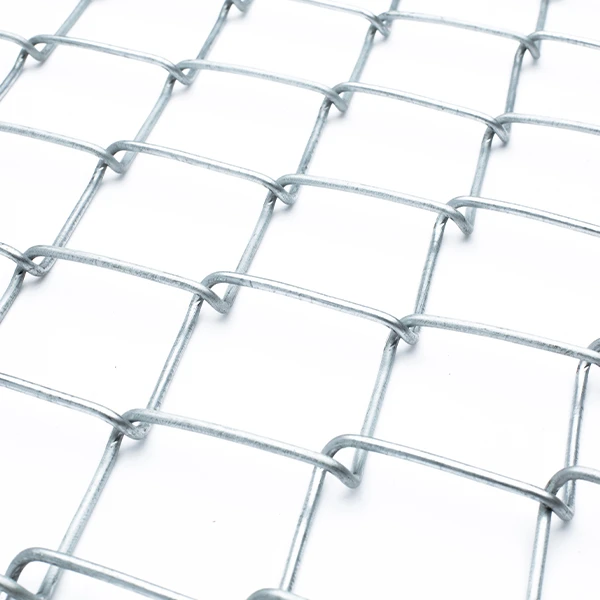

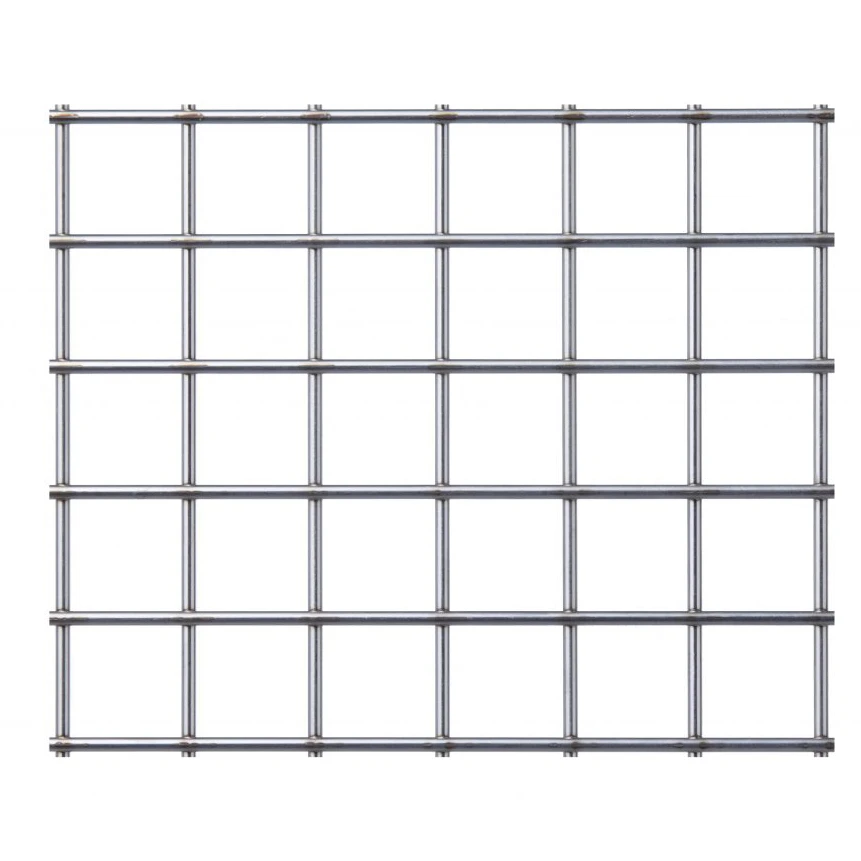

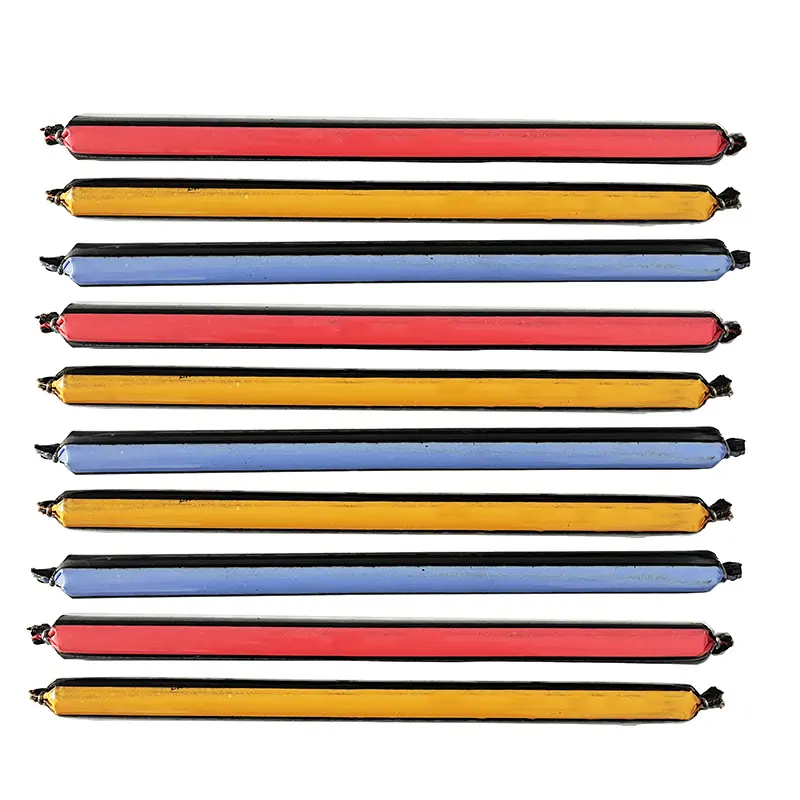

Jiufu's expanding shell anchor heads are used for roof and rib support in mining working areas. As an independent or auxiliary anchor support system, they can also be used to connect various components of mining equipment. Common specifications are 32mm, 35mm, 38mm, 42mm and 48mm. The material is cast iron and the surface treatment is sandblasting. Can be anchored in any rock formation, providing adequate anchorage. They are designed for anchoring in soft soil or hard rock. In good formations, the anchorage exceeds the ultimate strength of the steel anchor. All expansion shells require adequate formation in the anchorage area. The suitability of the anchorage and expansion shell used is best determined by physical load testing. The expansion shell is easy to install and instantly supports the work area by turning the bolt to create a point to anchor it in the hole. The casing is anchored to the rock, creating tension at the bottom of the borehole that transfers the load from the bolt head and plate to the rock through the casing.

What are the advantages of our expanding shell anchor head?

1. The installation method is simple, which can effectively save time and labor costs, as well as the cost of composite materials.

2. For mining applications.

3. Additional anti-corrosion protection extends service life.

4. The bolt shank is made of ordinary AP 600 steel rod 18,3 mm in compliance with ZN-97/AP-2 standards.

5. Various options of bolt forging heads are available.

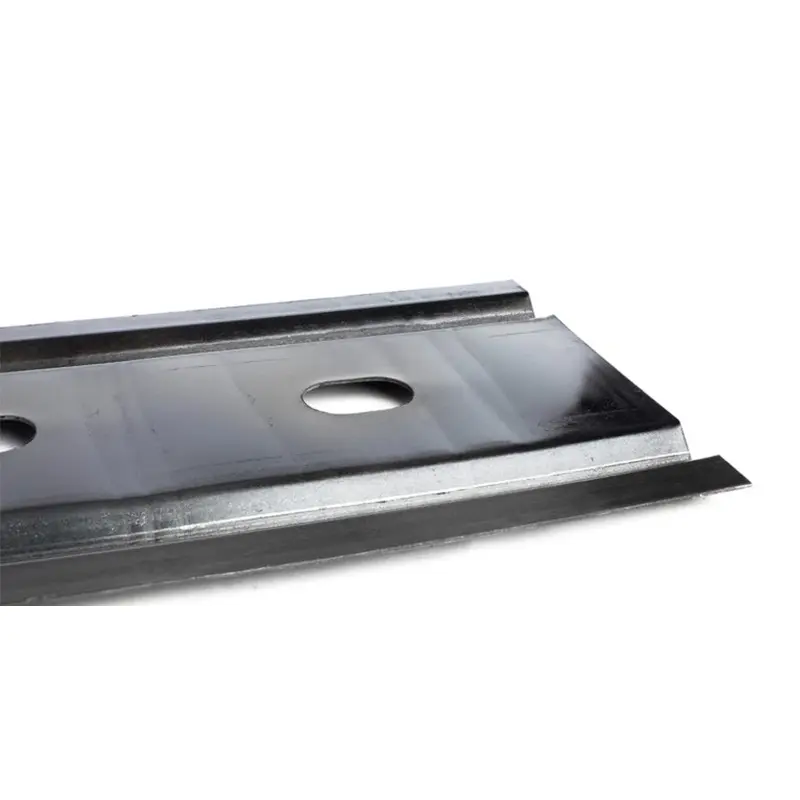

6. A variety of plate types are available.

Installation Process

How is the expanding shell anchor head installed?

1. Only use a rotary impact drill to drill holes, and then blow them clean with compressed air.

2. The hole diameter should be controlled within the tolerance range specified by the expansion shell used.

3. Screw the threaded rod completely into the tapered part of the extension housing as shown in the picture above.

4. If the expansion tank comes with a temporary plastic collar, this should be removed before inserting into the hole.

5. Before installation, the expansion shell should be tilted to avoid the risk of peeling.

6. Once installed, the lever should be rotated clockwise to "tilt" the two half-shells to lock the expansion shell without over-tightening the lever.

Product Application