Fully Threaded Concrete Strand

Composition

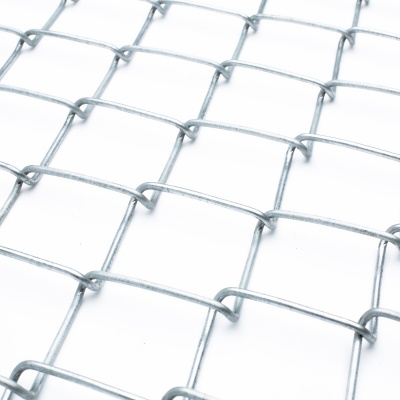

1.Steel wire:

The steel wire of the steel strand is made of high-strength high-quality steel wire. It is usually surface treated with galvanizing, aluminum plating, tin plating and other processes to prevent the steel wire from rusting.

2.Core wire:

The core wire is the internal support structure of the steel strand, usually using a steel core or fiber core to ensure the stability and bending resistance of the steel strand.

3.Coating:

The coating is a protective layer on the surface of the steel strand, and its function is to prevent the steel strand from corrosion, wear and oxidation.

In short, the components of steel strand include steel wire, core wire and coating. The quality and characteristics of these components will directly affect the performance and service life of steel strand. Therefore, when selecting steel strands, it is necessary to select the appropriate steel strand material and model according to the specific use needs and environment to ensure its safety and efficiency during use.

Installation Process

1.Material preparation:

First, materials and equipment such as steel strands and bolts need to be prepared.

2.Laying out and drawing bolts:

According to the design requirements, steel strands are laid on bridges, viaducts and other structures that require increased load-bearing and earthquake resistance. Then, insert the bolt into the end cover hole and tighten the bolt with a pneumatic wrench.

3.Stranding:

The prefabricated steel strands are laid side by side on temporary racks and then twisted.

4.Tension:

Pull the twisted steel strand to the predetermined position. This step requires the use of a tensioning machine to pull the strands to a predetermined length and tension.

5.Anchorage:

After completing the tensioning of the steel strand, the other end of the steel strand needs to be firmly fixed on the anchor for anchoring. When performing anchoring work, it is necessary to determine the type and quantity of anchors to be used based on the pulling force and the number of strands, and install all anchors evenly on each strand. After installation, the strands for tensioning and anchoring need to be placed for more than 24 hours to wait for the steel strands to solidify.

6.Spray anti-corrosion:

After the tensioning and anchoring are completed, the steel strands need to be spray-coated for anti-corrosion treatment.

7.Acceptance:

Finally, after complete curing, the strands are inspected and accepted. Inspection and acceptance need to include testing of the appearance, tensile strength and number of strands of the steel strands.

Advantage

1.Wear resistance: Because steel strands are made of multiple steel wires and have high surface hardness, their wear resistance is superior to other materials when the weight is the same.

2.High strength: Because the steel strand is twisted with multiple steel wires, it can withstand the lifting and transportation of a large number of heavy objects.

3.Corrosion resistance: The outside of steel strands is generally treated with galvanizing or other methods, which can effectively prevent the steel strands from being oxidized and corroded during use.

4.High temperature resistance: The hardness of the steel strand decreases after being heated, but its elasticity remains unchanged and can withstand heavy loads in high temperature environments.

5.Easy maintenance: Steel strands need to be cleaned and lubricated regularly to maintain their good condition.