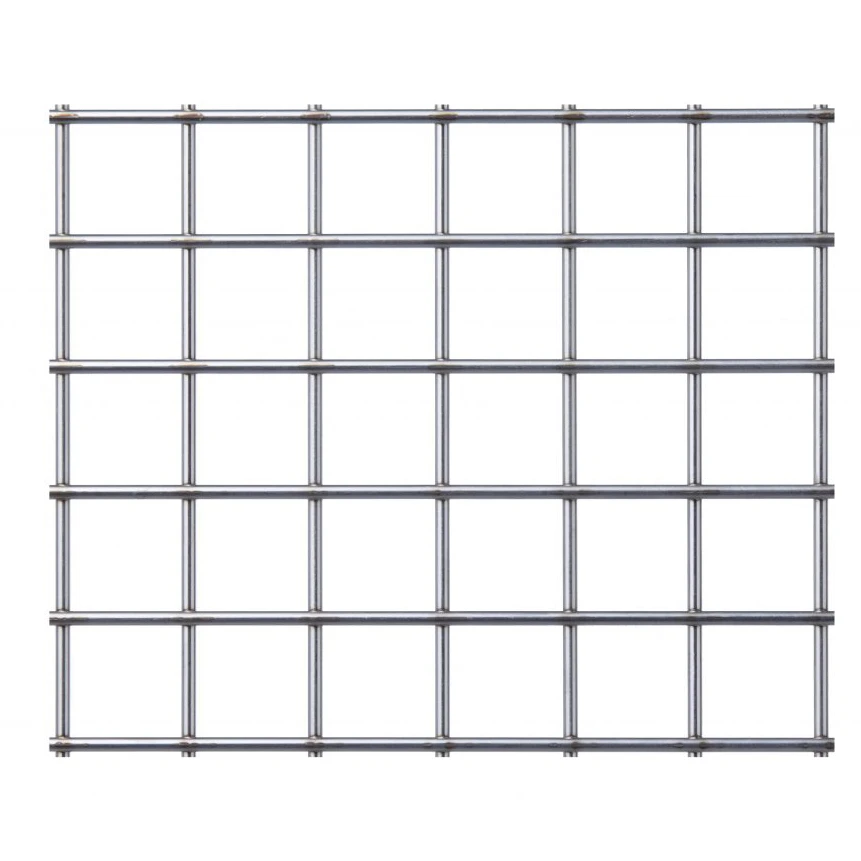

Mine welding wire support mesh

Product Introduction

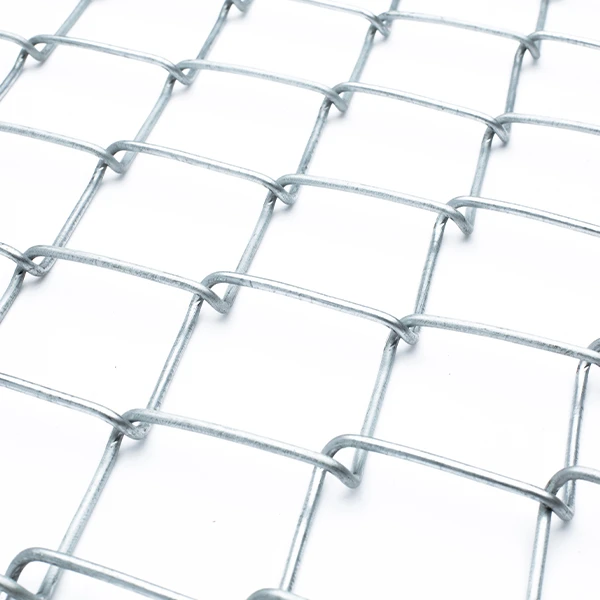

Mine welded wire mesh is a commonly used and widely used type of coal mine support network. It is an efficient and energy-saving support network. Welded wire mesh is made of thicker steel wire or steel bars and is spot welded into a tough square mesh structure. Strong welded joints provide double protection for tunnels compared to woven mesh such as barbed wire. Additionally, the sturdy construction increases stability and safety. It can make construction faster and easier. Welded mesh can be used in shotcrete applications, making construction faster, easier, and safer. Welded steel mesh is not only suitable for connecting steel bars in ordinary building structures, but can also be used in large buildings such as bridges and tunnels, and can play a role in various complex environments.

What are the advantages of Jiufu's welded mesh?

1. High precision and small tolerance.

2. Made of high-strength steel wire.

3.A variety of configurations and sizes are available.

4. Sturdy structure and long service life.

5. Easy to install and replace, reducing labor costs.

6. Suitable for shotcrete applications.

7. Used in loose strata to avoid rockfall.

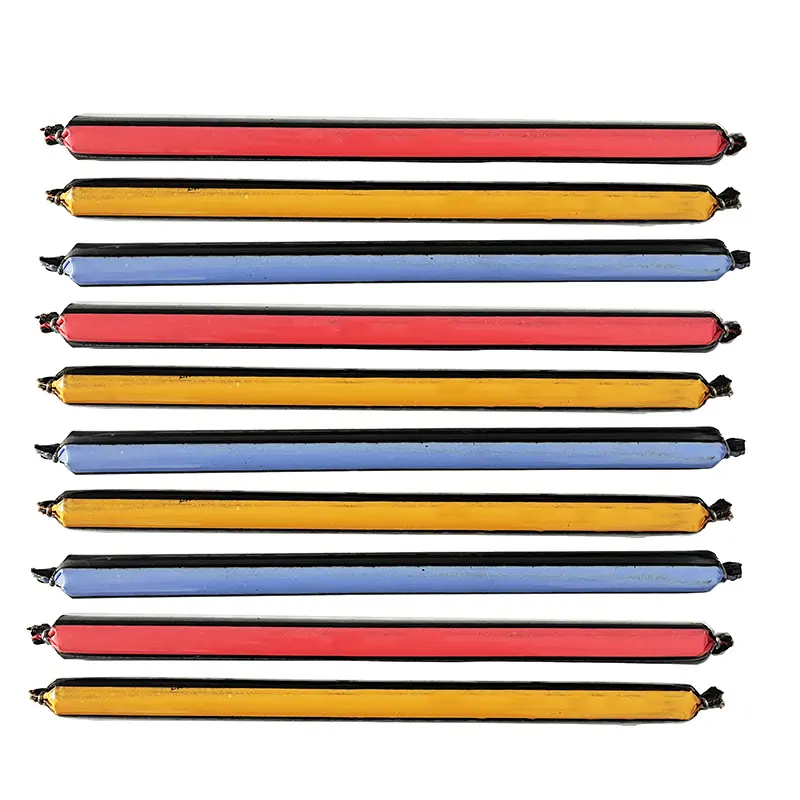

8. Available in galvanized or heavily galvanized finish for improved corrosion resistance.

9. Improve construction efficiency: As a construction auxiliary tool, welded steel mesh can help workers complete the arrangement of steel bars more quickly, greatly saving construction time.

Product Installation

How to install and use welded mesh?

1. Preparation work: Before using welded steel mesh, preparation work must be done first. Materials that need to be prepared include steel wire, welding gun, power supply, protective gloves, etc.

2. Clean the surface: Before using the steel welded mesh, the surface to be welded needs to be cleaned. Make sure the surface is clean and free of oil to improve welding quality.

3. Steel bar cutting: Cut the steel bars into appropriate lengths according to the required size and shape.

4. Set up a bracket: Before welding, a bracket needs to be set up to place the steel bars to be welded. This makes it easy to operate and ensures the steel bars don't move.

5. Welding: Place the cut steel bars on the bracket and weld with a handheld electric soldering iron or arc welding gun. It should be noted that the hand should be kept steady during welding, and the angle between the welding gun and the steel bar should be appropriate to avoid affecting the welding quality.

6. Check the quality: After the welding is completed, the solder joints need to be inspected. If looseness or defects are found, they must be repaired promptly.

7. Carry out anti-corrosion treatment: In order to extend the service life of the welded steel mesh, it is recommended to carry out anti-corrosion treatment after the welding is completed. You can use methods such as spray painting or applying preservatives.

8. Installation and use: After the above steps, the welded steel mesh can be installed and used. Depending on specific needs, it can be used for various purposes such as strengthening building structures and making guardrails.

Product Advantages

1.High precision and small tolerance.

2.Made of high-strength steel wire.

3.There are multiple configurations and sizes to choose from.

4.Sturdy structure and long service life.

5.Easy to install and replace, reducing labor costs.

6.Suitable for shotcrete applications.

7.Used in loose strata to avoid falling rocks.

8.Available in galvanized or heavily galvanized finishes for improved corrosion resistance.

9.Improve construction efficiency: As a construction auxiliary tool, welded steel mesh can help workers complete the layout of steel bars more quickly, greatly saving construction time.

Product Application