Self-drilling anchors are an essential tool in the construction and engineering industries, and they are known for their efficiency and reliability in securing materials to various substrates. These anchors are specifically designed to simplify the fastening process, eliminating the need for pre-drilling holes in many applications. This article will explore how self-drilling anchors work, their benefits, and their applications in various industries.

Understanding the Mechanism of Self-Drilling Anchors

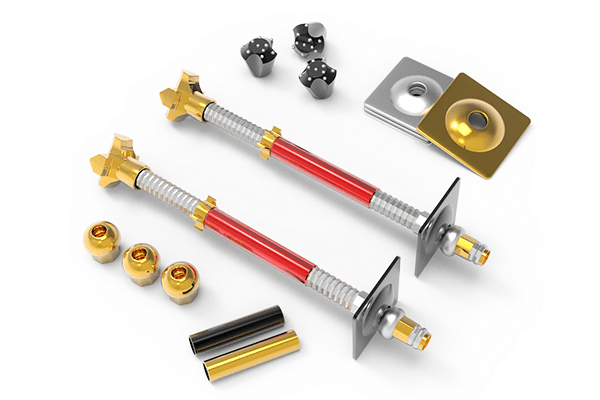

Self-drilling anchors are innovative fasteners that combine the drilling and anchoring process into a single step. The key to their functionality lies in their unique design, which typically includes a hardened, drill-like tip and a threaded shank. Here’s a breakdown of how they work:

- Drill Tip Design: The self-drilling anchor is equipped with a sharp, hardened tip that acts like a drill bit. When pressure is applied, either manually or with a power tool, this tip starts to cut into the substrate. The material for the drill tip is usually made from hardened steel or carbide, which allows it to penetrate hard materials such as concrete, brick, or metal without dulling quickly.

- Threaded Shank: As the anchor is driven into the substrate, the threaded shank follows the drill tip. The threads are designed to grip the sides of the drilled hole firmly, providing a secure hold. The threading also helps to pull the anchor deeper into the material, enhancing its grip and stability.

- Combined Drilling and Fastening: Unlike traditional anchors that require a separate step to drill a hole and then insert the anchor, self-drilling anchors perform both actions simultaneously. This dual-functionality significantly reduces installation time and labor, making them a popular choice in many fast-paced construction environments.

- Anchoring Mechanism: Once the anchor is fully inserted, the expansion mechanism (in some designs) activates. This might involve the anchor body expanding within the hole or the tip spreading out to create a tight, secure hold within the substrate.

Benefits of Using Self-Drilling Anchors

The use of self-drilling anchors offers several advantages, particularly in scenarios where efficiency and ease of installation are crucial:

- Time Efficiency: By combining drilling and fastening into a single operation, self-drilling anchors save a considerable amount of time. This is particularly beneficial on large projects where thousands of fasteners may need to be installed.

- Labor Cost Reduction: With fewer steps involved in the installation process, there is a reduced need for skilled labor, thus lowering overall labor costs.

- Versatility: Self-drilling anchors can be used in a variety of materials, including concrete, wood, metal, and drywall. This versatility makes them suitable for a wide range of applications, from securing electrical fixtures to mounting heavy structural components.

- Improved Safety: By minimizing the number of tools and steps required for installation, self-drilling anchors reduce the risk of accidents and injuries on the job site. There is also less chance of misalignment or incorrect installation, which can compromise the integrity of the fastened object.

Applications of Self-Drilling Anchors

Self-drilling anchors are used across various industries due to their adaptability and ease of use. Some common applications include:

- Construction: In the construction industry, self-drilling anchors are frequently used to attach steel, wood, or other materials to concrete or masonry. They are also used for installing drywall, ceiling panels, and insulation.

- Electrical Installations: Electricians use self-drilling anchors to secure wiring conduits, junction boxes, and other electrical components to walls and ceilings.

- Plumbing: Plumbers utilize self-drilling anchors to mount pipes and fixtures securely to walls or other structures, ensuring they remain stable and leak-free.

- HVAC Systems: Heating, ventilation, and air conditioning systems often require the installation of heavy components like air handlers and ductwork. Self-drilling anchors provide a reliable method for securing these systems in place.

Conclusion

Self-drilling anchors represent a significant advancement in fastening technology, offering a simple yet effective solution for attaching materials to various substrates. Their ability to combine drilling and anchoring into a single step not only speeds up the installation process but also reduces costs and improves safety. As industries continue to seek more efficient and reliable construction and installation methods, the use of self-drilling anchors is likely to grow, solidifying their place as a staple tool in modern construction and engineering.

Whether you’re a professional contractor or a DIY enthusiast, understanding the function and benefits of self-drilling anchors can help you choose the right fastener for your next project, ensuring strong, secure, and lasting results.

Post time: 8 月-23-2024