Are you looking for a solution to ensure the effective and efficient placement of your casing strings in demanding well conditions? This comprehensive guide dives into the world of centralizers, specifically focusing on the advantages and applications of bow spring centralizers. We'll explore their design, functionality, and the benefits they bring to your drilling operations, ultimately helping you make informed decisions for optimal wellbore integrity. This article is worth reading because it provides clear, concise, and practical information about bow spring centralizers and their critical role in modern drilling, with a focus on quality and cost-effectiveness.

1. What is a Centralizer and Why is it Important for Casing Operations?

A centralizer is a crucial component in well construction, designed to center the casing within the wellbore. This is particularly important for achieving optimal cement placement. Without proper centralization, the casing can rest against the wellbore wall, leading to an uneven annular space. This unevenness can result in poor cement coverage, which compromises the integrity of the well.

The primary function of a centralizer is to ensure that the casing is positioned in the center of the wellbore. This precise positioning is vital for several reasons. First, it creates a uniform annular space between the casing and the wellbore wall. This uniformity is essential for proper cement placement. Second, it helps to minimize differential sticking, where the casing becomes stuck against the wellbore wall due to pressure differences. Third, it facilitates efficient mud removal during the cementing process. The effectiveness of mud removal is critical to ensuring a strong bond between the cement and the formation.

Centralizers play a vital role in casing running, enabling the efficient and effective placement of casing strings. They directly influence cement placement, helping to create a solid seal that protects the well.

2. Bow Spring Centralizer: An In-Depth Look at the Design and Functionality

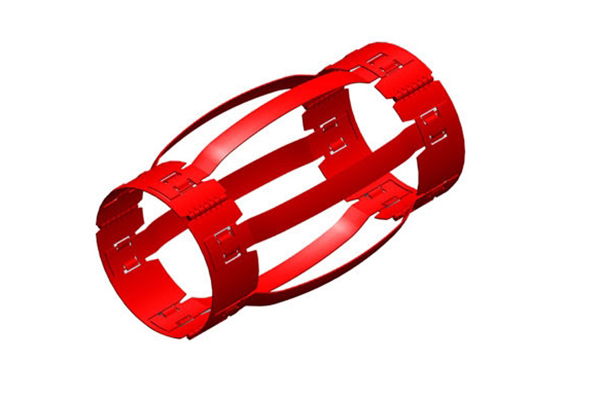

The bow spring centralizer is a popular choice, known for its straightforward design and effective performance. It is characterized by flexible bows made from spring steel. These bows are designed to compress during running, allowing the centralizer to pass through tight spots in the wellbore. Once past the restriction, the bows expand, centering the casing.

The design of a bow spring typically involves several bows arranged around a central hub. These bows are often connected to the hub by hinge points or integrated into a one-piece design. The flexibility of the bows is key to the bow spring centralizer's functionality. They can accommodate variations in the wellbore diameter and provide a degree of centralization, even in deviated wells. The bows are designed to maintain a consistent standoff from the wellbore wall, ensuring the casing remains centered.

The bow spring centralizer is designed to provide a restoring force that pushes the casing towards the center of the wellbore. This restoring force is crucial for maintaining centralization and enabling effective cement placement. The bows are designed to provide a balance between flexibility and restoring force, ensuring that the centralizer can pass through restrictions while still effectively centering the casing.

3. How Does a Bow Spring Centralizer Differ from Other Centralizer Types?

While bow spring centralizers are widely used, other centralizer types exist, each with its specific advantages and applications. Compared to solid body centralizers or rigid centralizers, bow spring centralizers offer superior flexibility and are better suited for deviated and irregular wellbores. Rigid centralizers, such as those made from solid metal, offer high strength but lack the flexibility of a bow spring. This means they may struggle to pass through tight spots or deviate wells.

Centek centralizer is a popular choice as well. The key distinction lies in the method of centralization. Bow spring centralizers rely on the outward force of the flexible bows, while other designs may use different mechanisms. For instance, some centralizers utilize a coil or a series of rings to provide the centering action. Understanding the differences between these centralizer types is critical for selecting the most suitable option for your specific well conditions. The choice of centralizer type will depend on several factors, including the wellbore geometry, the casing size, and the desired degree of centralization.

4. What Are the Key Benefits of Using Bow Spring Centralizers?

The benefits of using bow spring centralizers are numerous, making them a popular choice for various well construction projects. One of the primary advantages is their ability to accommodate deviated wells. Their flexible bows can easily navigate bends and irregularities in the wellbore, ensuring that the casing remains centered. This is particularly important in extended-reach and horizontal wells.

Another key benefit is the effective mud removal they facilitate. The design of the bow spring promotes even distribution of the casing within the wellbore, allowing for more efficient displacement of drilling mud. This leads to better cement bonding. Bow spring centralizers also offer a high restoring force, which means they provide a strong centering effect, even under pressure. This high restoring force is crucial for maintaining the position of the casing during the cementing process, ensuring optimal cement placement.

The design of a bow spring also minimizes the running force required to install the casing. This is an important consideration, especially in long and complex wellbores. Reduced running force can save time and reduce the risk of damaging the casing or wellbore. Furthermore, bow spring centralizers are often more cost-effective than other centralizer types, making them a practical choice for many projects.

5. How to Choose the Right Bow Spring Centralizer for Your Wellbore?

Choosing the right bow spring centralizer involves careful consideration of several factors. First and foremost, you need to know the wellbore size and the casing OD (outer diameter). The centralizer should be sized to provide adequate clearance in the wellbore while maintaining the appropriate standoff. Consider the annular clearance between the casing and the wellbore wall. The annular space must be sufficient to allow for effective cement placement and efficient mud removal.

The bow spring design offers a range of bow heights, so you can tailor your selection to your specific needs. The design should be carefully evaluated to ensure it can pass through any restrictions in the wellbore. Think about the presence of any under-reamed sections or tight spots that may challenge the centralizer. If you are working in a deviated well, look for centralizers with a high degree of flexibility. This will ensure that they can navigate the bends in the wellbore effectively.

Consider the operating conditions of the well, including pressure and temperature. The centralizer must be able to withstand these conditions without compromising its performance. If you are operating in high-pressure or high-temperature environments, you may need to select a centralizer made from specialized materials. Finally, consider the vendor’s product service and support. Choosing a reputable supplier with a strong track record can ensure that you get high-quality products and excellent service. You can also contact us to find out which centralizer is best for you.

6. Are There Different Designs of Bow Spring Centralizers?

Yes, bow spring centralizers are available in various designs to suit diverse wellbore conditions and operational requirements. One common variation is the one-piece design, where the bows and central hub are manufactured as a single unit. This design offers inherent strength and simplicity, making it ideal for straightforward applications. Another variation features welded bows. Welding offers added durability, making the centralizer suitable for more demanding environments.

Another design feature is the type of end collars used. These collars can be either slip-on or hinged. Slip-on collars are simple to install and are suitable for most applications. Hinged collars offer greater flexibility and can accommodate tighter tolerances, making them useful for navigating complex wellbore geometries.

The materials used in the manufacture of the bows also vary. The most common material is high-strength spring steel, but other materials may be used for specific applications. For example, stainless steel is often used in corrosive environments, while other alloys may be used for high-temperature or high-pressure applications. The choice of material depends on the specific well conditions and operational requirements. The goal is to ensure that the centralizer can withstand the rigors of the drilling environment and maintain its structural integrity throughout the casing running and cementing process.

7. What Role Does the Hinge Play in Bow Spring Centralizer Performance?

The hinge is an important element in the design of many bow spring centralizers. It is especially critical in applications that require flexibility and the ability to navigate irregular wellbores. The hinge allows the bows to move independently, which is essential for accommodating deviations and tight spots.

The presence of a hinge allows each bow to adjust to the wellbore wall independently. This is important for maintaining a consistent standoff and ensuring proper centralization, even in non-uniform wellbores. The hinge design also affects the running force of the centralizer. A well-designed hinge will minimize the running force needed to pass the centralizer through restrictions, saving time and reducing the risk of damage.

The design of the hinge also influences the restoring force of the centralizer. The hinge must be strong enough to withstand the forces exerted on the bows while still allowing them to flex. The hinge is designed to ensure that the bows have the necessary flexibility to center the casing effectively.

8. Can Bow Spring Centralizers Be Used in Close Tolerance Applications?

Yes, bow spring centralizers can be used in close tolerance applications, provided the design is specifically engineered for such requirements. In close tolerance applications, the annular clearance between the casing and the wellbore is minimal, which means the centralizers must be designed to operate with very little space to spare.

Bow spring centralizers used in close tolerance applications often have a low profile design, allowing them to pass through restricted areas without getting stuck. These centralizers may feature flexible bows and hinge designs to accommodate the tight space. They are designed to provide effective centralization while still maintaining a smooth run-in-hole (RIH). The design of the bows and the overall profile of the centralizer are carefully engineered to minimize friction and the force required to run the casing.

In these close tolerance applications, the centralizer's ability to compress is essential. The bows must be able to collapse sufficiently to pass through the restricted areas. This requires careful selection of materials and design elements, with a focus on flexibility and durability. In close tolerance applications, the selection of the right centralizer type is crucial. It is recommended to consult with an engineer to determine the optimal design for your specific well conditions.

9. What Factors Influence the Running Force of a Bow Spring Centralizer?

The running force of a bow spring centralizer refers to the amount of force required to push the centralizer down the wellbore. Several factors influence the running force, and understanding these factors is important for optimizing the casing running process. The design of the bows is a primary factor. The shape, size, and number of bows will directly affect the running force. Bows that are more rigid or have a larger contact area with the wellbore wall will require a higher running force.

The material used in the bows also influences the running force. Steel with a higher yield strength will require more force to compress the bows. The OD of the casing and the ID of the wellbore are also significant factors. A smaller annular space will result in a higher running force because the bows have less room to flex. The presence of any restrictions in the wellbore, such as tight spots or doglegs, will also increase the running force.

The use of lubricants can help to minimize the running force. The presence of drilling mud, or other fluids, can reduce friction and make it easier to run the centralizer. Proper lubrication can significantly reduce the force required to run the casing.

The condition of the wellbore also plays a role. A smooth, clean wellbore will result in a lower running force than a wellbore with rough surfaces or debris. Regular inspection and maintenance of the centralizer are also essential. Damaged or worn bows can increase the running force and reduce the effectiveness of the centralizer.

10. Where to Buy High-Quality Bow Spring Centralizers?

When purchasing bow spring centralizers, it's essential to source them from a reliable supplier. Look for suppliers who manufacture their products to API (American Petroleum Institute) standards, such as API 10D. This certification ensures that the centralizers meet industry-accepted quality and performance standards.

Consider the supplier’s experience and track record. A supplier with a long history in the industry is more likely to provide high-quality products and reliable service. Also, make sure to review customer testimonials and case studies. These provide insight into the supplier's reputation and the performance of their products in real-world applications. Look for a supplier that provides comprehensive technical support and customer service. You might want to contact us. A responsive and knowledgeable team can help you select the right centralizers for your specific well conditions and provide assistance if any issues arise.

Evaluate the supplier’s manufacturing process and quality control procedures. A supplier with a robust quality control system is more likely to deliver consistent, high-quality products. You could ask the supplier about their quality assurance procedures, including inspection and testing protocols. Assess the supplier's ability to meet your specific requirements. Some suppliers may offer customized centralizers or have the flexibility to accommodate special requests. Consider the supplier's logistics and delivery capabilities. Ensure that they can deliver the products on time and in the desired quantities.

Choose a supplier that offers competitive pricing without compromising quality. Cost is always a consideration, but don't sacrifice quality to save money. The long-term performance and reliability of the centralizers are much more important than the initial price. Look for suppliers that are committed to innovation and continuous improvement. A supplier that invests in research and development is more likely to offer cutting-edge products and solutions.

Summary

In summary, here are the key takeaways:

- Centralizers are essential for optimal casing placement and cementing.

- Bow spring centralizers offer flexibility, making them suitable for deviated wells.

- Choose the right centralizer based on wellbore size, and operating conditions.

- The hinge and bow designs affect the running force and performance.

- Source centralizers from reputable suppliers adhering to API standards.

- Proper use of centralizers results in increased well productivity and lifespan, and reduces overall project cost.

- Contact us to discuss your project requirements.

Post time: 2 月-10-2025