Bolts, nuts, and screws – the unsung heroes of countless construction, mining, and tunneling projects. These fasteners might seem simple, but selecting the correct type and size is crucial for ensuring the safety, durability, and longevity of your structures and equipment. This article will guide you through the essential considerations when choosing the right nut and bolt for your specific needs, helping you make informed decisions that can save time, money, and potential headaches down the line. Understanding the nuances of bolt size, type of bolt, and the materials they're made from is paramount in our industry, and this guide provides the insights you need.

1. What Exactly Are Bolts and Screws, and Why Do They Matter?

At their core, bolts and screws are types of fasteners designed to hold materials together. They are essential components in everything from heavy machinery used in mining operations to the structural framework of buildings. The seemingly simple act of joining two pieces of material relies heavily on the integrity of these small components. A correctly chosen bolt, when used with a nut, creates a strong, reliable connection. Conversely, using the wrong type of bolt or an incorrectly sized screw can lead to structural failure, equipment malfunctions, and, most importantly, safety hazards. Think about the immense forces at play in a tunneling project – every threaded fastener needs to perform flawlessly.

The reliability of a bolted joint directly impacts the overall integrity of a structure or machine. Whether you're securing support beams in a mine shaft or assembling heavy equipment, the choice of bolt is a critical decision. Even seemingly small variations, like the thread pitch or the bolt head design, can significantly affect the strength and durability of the connection. Without robust bolts and screws, our industry simply couldn't function safely or efficiently.

2. Bolts vs. Screws: What's the Key Difference for Your Projects?

While often used interchangeably, bolts and screws have distinct differences that are important to understand. A bolt is typically designed to be inserted through pre-drilled holes and is always used with nuts to clamp materials together. The nut provides the clamping force against the bolt head. Think of it as a two-part system. Screws, on the other hand, usually thread directly into the material being joined, creating their own internal thread as they are tightened.

| Feature | Bolt | Screw |

|---|---|---|

| Requires a Nut | Yes | Usually No |

| Method of Fastening | Clamping force between bolt head and nut | Threads directly into material |

| Typical Applications | Structural connections, machinery assembly | Woodworking, attaching components to equipment |

For professionals in construction and mining, understanding this distinction is crucial. For high-load applications requiring robust connections, such as securing steel beams or assembling machinery, bolts are generally the preferred choice due to the added security provided by the nut. While screws have their place, they might be more suitable for lighter-duty applications within our industry. Knowing when to use a bolt versus a screw is a fundamental aspect of sound engineering practice.

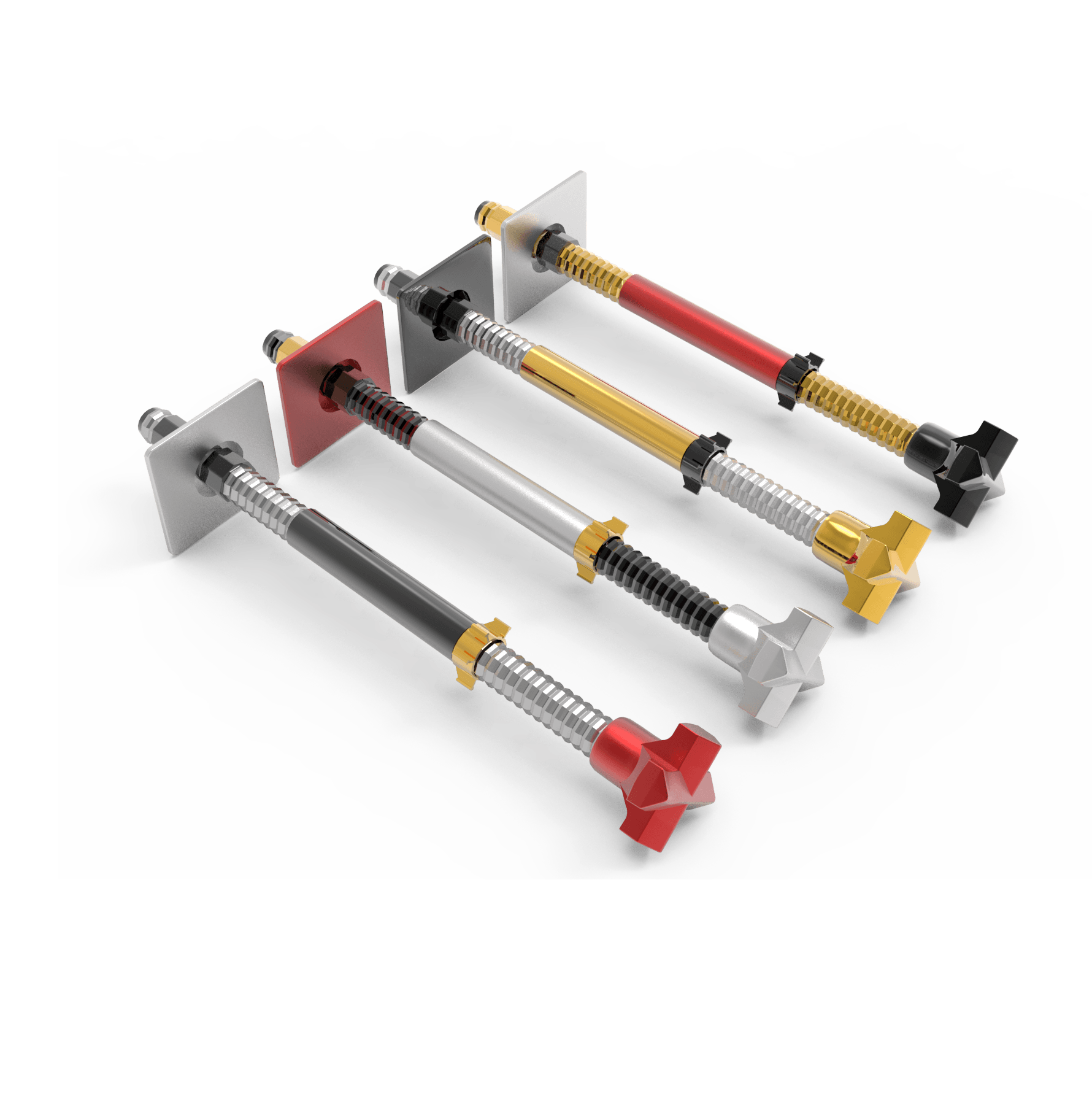

The world of bolts is surprisingly diverse, with each type of bolt designed for specific applications and load requirements. Understanding these variations is crucial for making the right selection. Here are a few common bolt types you'll encounter:

-

Hex Bolts: These are perhaps the most common type, featuring a six-sided bolt head that can be easily tightened with a wrench or socket. They are versatile and used in a wide range of applications. You'll find many hex bolts in structural steel connections.

-

Carriage Bolts: Characterized by a domed or button-shaped bolt head with a square shoulder underneath, carriage bolt are often used in timber construction. The square shoulder prevents the bolt from turning when the nut is tightened.

-

Anchor Bolts: Specifically designed for attaching objects to concrete, anchor bolt come in various shapes and sizes, providing a strong and reliable connection. These are critical in foundation work and securing equipment to concrete pads.

-

Eye Bolts: Featuring a loop at the threaded end, eye bolts are used to create attachment points for ropes, cables, or lifting hardware. They are essential for rigging and lifting operations in both construction and mining.

-

Structural Bolts: Designed for high-strength connections in steel structures, structural bolts often have specific head markings indicating their grade and strength. These bolts are critical for ensuring the integrity of buildings and bridges.

-

Stud Bolts: These are headless threaded bolt that are screwed into a tapped hole at both ends. They are often used for connecting flanges in piping systems.

This is just a glimpse into the variety of bolt types available. Choosing the correct type of bolt depends on factors like the materials being joined, the applied load, and the environmental conditions.

4. Beyond the Basics: Understanding Bolt Head Types and Their Applications

The shape of the bolt head is not just an aesthetic choice; it directly influences how the bolt can be installed and the type of tool required. Different bolt head designs also offer varying levels of accessibility and security.

-

Hex Head: As mentioned earlier, the hex head is a standard and versatile design, easily gripped by wrenches and sockets.

-

Square Head: Less common now but still found in older structures, square heads provide a good gripping surface.

-

Round Head: Often used in conjunction with a square neck (as seen in carriage bolt), round heads provide a tamper-resistant finish once installed.

-

Flat Head (Countersunk): Designed to sit flush with the surface of the material, countersunk bolt require a countersunk hole for installation. They provide a clean, smooth finish.

-

Button Head: Offering a low profile, button heads are often used for aesthetic purposes or in applications where clearance is limited.

-

Flange Bolt Head: These bolts come with an integrated flange under the head, which distributes the clamping load over a larger area, eliminating the need for a separate washer in some applications.

Understanding the different bolt head types ensures you select a fastener that can be properly installed and will perform as intended. For instance, using a countersunk bolt where a raised head is required could compromise the strength of the joint.

5. The Importance of the Thread: How Does the Bolt Thread Affect Performance?

The thread of a bolt is what allows it to grip and hold materials together. Understanding thread characteristics is vital for selecting the appropriate fastener. Key aspects of the thread include:

-

Thread Pitch: This refers to the distance between the peak of one thread and the next, often measured in threads per inch (tpi) for imperial bolts or in millimeters for metric bolt. A coarser thread pitch (fewer tpi) is typically used for faster installation and softer materials, while a finer thread pitch provides greater holding power and is preferred for harder materials and applications requiring precise adjustments.

-

Thread Size: This refers to the nominal diameter of the bolt. Bolt size is a critical factor in determining the strength and load-bearing capacity of the bolt.

-

Thread Length: The portion of the shank that is fully threaded. For certain applications, a fully threaded bolt might be necessary, while others may only require partial threading.

-

Thread Type: Common thread types include Unified National Coarse (UNC) and Unified National Fine (UNF) for imperial bolts, and various metric thread standards.

The interaction between the bolt thread and the nut thread is what creates the clamping force. Mismatched thread types or pitches will result in a weak or impossible connection. Always ensure the nut and bolt have compatible threads. Properly engaging the screw thread is fundamental to a secure fasten.

6. Material Matters: What Are the Best Bolt Materials for Demanding Environments?

The material a bolt is made from significantly impacts its strength, corrosion resistance, and suitability for different environments. Choosing the right bolt materials is especially important in the often harsh conditions of construction and mining.

-

Carbon Steel: A common and cost-effective material, carbon steel bolts are made in various grades, offering different levels of strength. However, they are susceptible to rust and corrosion, making them less suitable for outdoor or corrosive environments without proper coatings.

-

Alloy Steel: By adding elements like chromium and molybdenum, alloy steel bolts offer increased strength and toughness compared to carbon steel. These are often used in high-stress applications.

-

Stainless Steel: Offering excellent corrosion resistance, stainless steel bolts use chromium as a key alloying element. They are ideal for applications exposed to moisture, chemicals, or saltwater. Different grades of stainless steel offer varying levels of corrosion resistance and strength.

-

Brass: Known for its corrosion resistance and electrical conductivity, brass bolts are often used in marine and electrical applications.

-

Nylon and Other Plastics: These materials offer corrosion resistance and are lightweight, but they are generally used for lighter-duty applications where high strength is not required.

For industries like mining and tunneling, where exposure to water, chemicals, and extreme temperatures is common, selecting bolt materials with adequate corrosion resistance is crucial for longevity and safety.

7. Decoding the Numbers: How Do You Determine the Correct Bolt Size and Length?

Choosing the correct bolt size and bolt length is critical for a secure and effective connection. An undersized bolt may not have the necessary strength, while an oversized bolt might not fit properly or could be unnecessarily expensive.

-

Bolt Diameter: This is typically the first number you'll see when specifying a bolt size (e.g., M8, 1/2"). It refers to the diameter of the shank. The required diameter depends on the load the bolt will need to bear.

-

Bolt Length: This is the distance from under the bolt head to the threaded end. It's crucial to choose a bolt length that allows for full engagement of the nut without excessive thread protruding. A general rule of thumb is that at least two threads should be visible beyond the nut when tightened.

For metric bolts, the size is usually indicated by an "M" followed by the nominal diameter in millimeters (e.g., M10). For imperial bolts, the size is given in inches (e.g., 1/4").

To determine the correct bolt length, measure the thickness of the materials being joined and add the thickness of the washer (if used) and the desired amount of thread protrusion beyond the nut. Accurate bolt measurements are essential to avoid issues during installation.

8. Nuts and Bolts Go Hand-in-Hand: Selecting the Right Nut for a Secure Fasten

A bolt is only as good as the nut it's paired with. Choosing the right nut is just as important as selecting the correct bolt. Like bolts, nuts come in various types and materials:

-

Hex Nuts: The standard nut, matching the hexagonal shape of most bolt heads.

-

Lock Nuts: Designed to resist bolt loosening due to vibration or movement. Types include nylon insert lock nuts (nylocks), serrated flange nuts, and castle nuts (which use a cotter pin for locking).

-

Flange Nuts: Similar to flange bolt heads, these hex nuts have an integrated flange that distributes the clamping load.

-

Jam Nuts: Thin hex nuts used with nuts to lock another nut in place, preventing it from loosening.

-

Wing Nuts: Feature "wings" for easy hand tightening, often used in applications requiring frequent adjustments.

-

Cap Nuts (Acorn Nuts): Have a domed top that covers the threaded end of the bolt for a finished look or to protect the threads.

When selecting a nut, ensure it matches the bolt's thread type and size. The nut material should also be compatible with the bolt material to prevent galvanic corrosion in certain environments. For critical applications, especially where vibration is a concern, using lock nuts is highly recommended to prevent bolt loosening.

9. Keeping it Tight: Best Practices for Installation and Preventing Bolt Loosening

Proper installation is crucial to achieving the intended strength and reliability of a bolted joint. Following best practices can prevent premature failure and ensure long-term performance.

-

Use the Right Tools: Employ the correct size wrench or socket to tighten nuts to hold the bolt in place. Avoid using worn or damaged tools. For specific torque requirements, use a torque wrench.

-

Don't Overtighten: Overtightening can damage the thread or the materials being joined. Refer to manufacturer specifications for recommended torque values.

-

Use Washers: Washers distribute the clamping load and protect the surfaces being joined. Flat washers and lock washers serve different purposes.

-

Consider Thread Lubrication: Lubricating the screw thread can help achieve accurate torque and prevent seizing, especially with stainless steel bolts.

-

Implement Locking Mechanisms: For applications prone to vibration, use lock nuts, jam nuts, or threadlocking compounds to prevent bolt loosening.

Regular inspection of bolted joint is also important, especially in high-stress applications. Look for signs of bolt loosening or corrosion. Implementing a preventative maintenance schedule can identify potential issues before they become critical.

10. Sourcing with Confidence: Key Considerations When Purchasing Bolts and Nuts

Purchasing bolts and nuts requires careful consideration to ensure you're getting quality products that meet your specific needs. As Allen from China, a factory owner specializing in Self-Drilling Anchor Systems and Drilling Tools, understands, quality and reliability are paramount. For buyers like Mark Davis in the USA, here are some key considerations:

-

Quality and Certifications: Look for suppliers who adhere to international standards like ISO. High-quality materials and manufacturing processes are essential for reliable performance. Don't hesitate to ask for material certifications.

-

Material Grade and Strength: Ensure the bolts and nuts you are purchasing are made from the appropriate material and have the required strength grade for your application.

-

Accurate Sizing and Threading: Verify that the bolt size, bolt length, and thread pitch meet your specifications. Inconsistent thread can lead to installation problems and weakened connections.

-

Corrosion Resistance: If the application involves exposure to corrosive environments, choose fasteners with appropriate coatings or materials like stainless steel.

-

Supplier Reputation and Reliability: Work with reputable suppliers who have a track record of delivering quality products on time. Effective communication is crucial to avoid the pain points Mark Davis experiences. Exhibitions are a good way to find reliable suppliers.

-

Logistics and Payment Methods: Discuss shipping options and payment terms upfront to avoid delays and misunderstandings.

-

Cost vs. Value: While cost is a factor, prioritize quality and reliability. Cheaper, lower-quality fasteners can lead to costly failures down the line.

By carefully considering these factors, you can source bolts and nuts with confidence, ensuring the success and safety of your projects. As a B2B supplier with 7 production lines, we understand the importance of providing high-quality materials, and we export our products to countries like the USA, North America, Europe, and Australia. Our potential customer identities include construction companies, mining companies, tunneling contractors, and geotechnical engineering firms. We pride ourselves on our comprehensive product range and compliance with international safety standards.

Key Takeaways:

- Bolts and nuts are critical fasteners in construction and mining.

- Understanding the different types of bolts and their applications is essential.

- The thread characteristics significantly impact performance.

- Choosing the right bolt materials is crucial for durability and corrosion resistance.

- Accurate bolt size and bolt length are vital for a secure connection.

- Selecting the appropriate nut is just as important as choosing the right bolt.

- Proper installation techniques prevent bolt loosening.

- Source bolts and nuts from reputable suppliers, prioritizing quality and certifications.

For more information on high-quality fasteners, including anchor bars, anchor bits, and anchor nuts, visit our website. We also offer a wide range of drilling equipment, including tapered drill rods and drill button bits. Explore our selection of reliable self drilling anchor tools today.

Post time: 12 月-30-2024