Goldcorp, a globally active mine operator, is the largest gold miner in Ontario’s north-east. Near the town of Chapleau in Ontario, Canada, the company is making new gold deposits accessible with the Borden Gold Project.

The excavation of a portal and the construction of an access ramp started in the first quarter of 2017. A 30,000t bulk sample will be extracted to confirm the existence of gold deposits in this hard rock mine.

Even prior to accessing the portal, DSI Underground Canada formed part of a technical committee to assist in the rapid development of the mine. Experienced DSI Underground engineers proposed alternate solutions to the generic methods of ground support. The typical resin and rebar support that is used in northern Canada would have prolonged the startup due to the limitations of extreme temperatures.

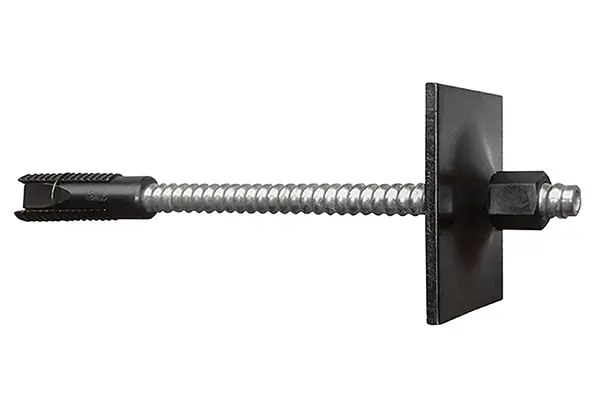

For this reason, the mine decided to use the DSI Hollow Bar Anchor as an efficient ground support product to ensure the rapid development of the portal. The DSI Hollow Bar Bolt is installed using either air or hydraulically-driven rotary drills, which ensures high rates of installation and good directional stability. Furthermore, the ground within the borehole is consolidated.

With resin grout, the use of which is a potential issue due to unsuspected climate, the idea is to create active first-pass support by tensioning the bolt with the shell that thus contains the rock mass in tension. This way, the bolts can be grouted at a future date. Now, a time-saving and innovative alternative to this system is available: DSI Underground’s new, pumpable resin system. This method ensures a rapid development cycle. Thanks to the use of this resin system, the Borden Mine will be able to drive the portal quickly safely, and efficiently access the bulk sample.

Post time: Nov-04-2024