Anchor bolts are essential components that hold structures together, providing the needed stability and safety. But do you know how to tighten them properly? In this guide, we’ll explore everything about bolts, nuts, and the tools you need. Whether you’re a DIY enthusiast or a professional, learning the correct way to tighten anchor bolts is crucial. Read on to discover the secrets behind secure and reliable fastening.

Understanding the Importance of Properly Tightened Anchor Bolts

When it comes to construction and engineering projects, anchor bolts play a vital role. They connect structural elements to concrete, ensuring everything stays in place. If these bolts aren’t properly tightened, it can lead to serious issues like structural failures.

Why is tightening so important?

- Safety: A loose bolt can compromise the entire structure.

- Strength: Properly tightened bolts achieve the desired tensile strength.

- Longevity: Correct installation extends the life of the product.

By applying the right amount of torque, you ensure that the anchor bolt holds firmly, preventing the nut from coming loose over time.

What Tools Do You Need to Tighten Nuts and Bolts?

To get the job done right, you’ll need the correct tools. Here’s a list of essential tools for tightening nuts and bolts:

- Wrench: A basic tool for turning bolts and nuts.

- Torque Wrench: Ensures you apply the correct amount of torque.

- Socket Set: Provides various sizes to fit different bolts.

- Screwdriver: For bolts with a screwdriver head.

Using the right tool not only makes the job easier but also ensures the bolt is tightened to the correct specification. Remember, using an incorrect tool can lead to over-tightening or under-tightening, causing the bolt to fail.

How Do Threads Affect Bolt Tightening?

The thread of a bolt is more than just a spiral groove. It’s crucial for how the nut and bolt interact.

- Bolts with a typical thread allow for smooth tightening.

- The thread’s condition affects how much torque is needed.

- Damaged threads can lead to improper tightening and load issues.

Before tightening, always check the thread for any damage or debris. Clean threads ensure that the nut can be tightened without excessive force, leading to a secure and tight fit.

Can You Tighten Anchor Bolts By Hand?

You might wonder if it’s okay to tighten anchor bolts by hand. While you can start threading the nut by hand to ensure it’s properly aligned, relying solely on hand-tightening isn’t recommended.

Why?

- Insufficient Torque: Hand tightening doesn’t apply enough force.

- Risk of Loosening: Bolts may become loose under load.

- Safety Concerns: The installation might not meet safety standards.

For proper installation, use a wrench or especially a torque wrench to apply the correct amount of torque.

Why Use a Torque Wrench for Anchor Bolts?

A torque wrench is a specialized tool that measures the amount of torque applied to a bolt.

- Precision: Ensures bolts are tightened to the manufacturer’s specifications.

- Prevent Over-Tightening: Avoids damaging the bolt or the material.

- Consistent Results: Provides uniform tension across all bolts.

By using a torque wrench, you can ensure that every bolt is tightened properly, reducing the risk of bolts coming loose or failing.

Answering Common Questions About Torque and Strength

Question: How much torque should be applied when tightening anchor bolts?

Answer: The required torque depends on the bolt’s size, material, and the application’s requirements. Always refer to the manufacturer’s guidelines or engineering specifications.

Question: What happens if I over-tighten a bolt?

Answer: Over-tightening can stretch the bolt beyond its elastic limit, reducing its tensile strength. This can lead to bolt failure under load.

Question: Can I reuse anchor bolts?

Answer: It’s generally not recommended to reuse anchor bolts, especially if they have been subjected to significant load or tightening cycles. Metal fatigue can lead to failure.

How to Prevent Nuts from Coming Loose?

A nut coming loose can lead to serious problems. Here’s how to prevent it:

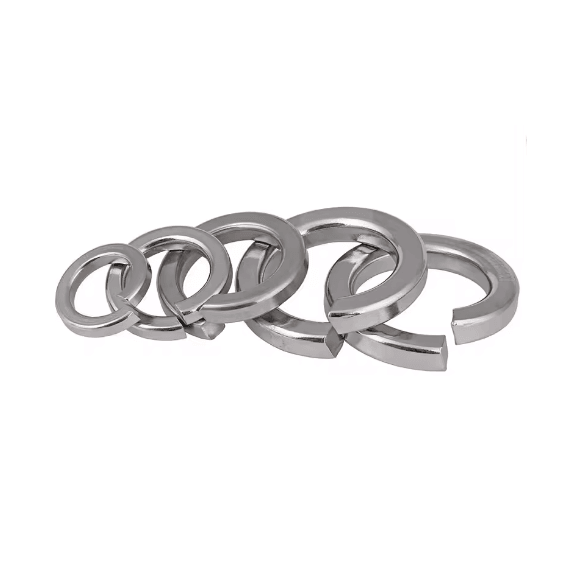

- Use Lock Washers: Increases friction between the nut and the surface.

- Apply Thread Locker: A chemical adhesive that prevents loosening.

- Proper Torque: Ensure the nut is tightened to the correct torque.

- Regular Maintenance: Check and tighten nuts as part of routine maintenance.

By taking these steps, you can prevent nuts from coming loose and ensure the security of your installation.

The Role of Surface Friction in Tightening Bolts

Surface friction plays a significant role in the tightening process.

- Friction Between Threads: Affects how much torque is converted into clamping force.

- Lubricated vs. Dry Threads: Lubrication reduces friction, requiring less torque for the same tension.

- Material Surface: Different materials have varying friction coefficients.

Understanding surface friction helps you apply the correct torque and achieve the desired tensile strength without over-tightening.

What Happens If Anchor Bolts Become Loose?

If an anchor bolt becomes loose, several issues can arise:

- Structural Instability: The load may not be properly supported.

- Safety Hazards: Increased risk of accidents.

- Damage to Materials: Movement can cause wear or breakage.

Regular inspections are crucial. If you notice a bolt is loose, address it immediately by re-tightening or replacing it if necessary.

Tips for Correct Installation and Maintenance

To keep your anchor bolts secure, follow these tips:

- Use the Right Tools: A calibrated torque wrench is essential.

- Follow Specifications: Always adhere to the manufacturer’s guidelines.

- Check Threads: Ensure threads are clean and undamaged before installation.

- Avoid Over-Tightening: More torque isn’t always better.

- Routine Maintenance: Periodically check bolts for signs of loosening or corrosion.

By following these steps, you ensure that your bolts remain tight and your structure stays safe.

Why Do Anchor Bolts Come Loose and How to Prevent It?

Question: What causes bolts to become loose?

Answer: Several factors can lead to loosening:

- Vibration: Repeated motion can shake bolts loose.

- Temperature Changes: Expansion and contraction can affect tightness.

- Improper Installation: Not applying the correct torque or using the wrong tools.

How to Prevent It?

- Use Locking Mechanisms: Such as lock nuts or thread lockers.

- Properly Tighten During Installation: Using the correct torque and tools.

- Regular Checks: Include bolt inspections in your maintenance schedule.

Conclusion: Ensuring Safety Through Proper Bolt Tightening

Tightening anchor bolts might seem straightforward, but there’s a lot to consider. From selecting the right tool to understanding threads and torque, each step is vital. By ensuring bolts are properly tightened, you contribute to the overall safety and integrity of the project.

Remember:

- Use a torque wrench for accuracy.

- Check threads and surfaces before installation.

- Prevent nuts from coming loose with proper techniques.

- Regular maintenance is key to safety.

- Don’t assume; learn and apply the correct methods.

Key Points to Remember

- Always use the correct tools, like a torque wrench, for tightening bolts.

- Check the threads for damage or debris before installation.

- Apply the manufacturer’s recommended torque to ensure proper tightness.

- Prevent nuts from coming loose by using lock washers or thread lockers.

- Regular maintenance and inspections help catch any issues early.

Explore Our Related Products

- Nut: High-quality nuts designed for secure fastening.

- Washer: Durable washers to distribute load and prevent loosening.

- Expansion Shell Anchor Bolt: Reliable anchor bolts for various applications.

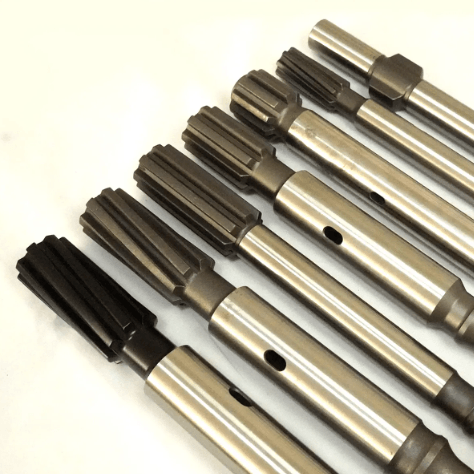

- Shank adapters: Essential tools for drilling projects.

By mastering the art of tightening anchor bolts, you’re not just completing a task; you’re building something that lasts. Use this guide to help you along the way, and don’t hesitate to reach out if you have questions. Thanks for reading, and happy building!# Achieving Structural Integrity: Proper Installation of Anchor Bolts and Nuts

Proper installation of anchor bolts and nuts is crucial for ensuring the structural integrity of any construction project. This comprehensive guide will delve into the essentials of anchor bolt installation, highlighting the importance of minimum thread protrusion beyond the nut and providing practical tips to avoid common pitfalls. Whether you’re a seasoned professional or new to the industry, understanding these concepts is essential for the safety and longevity of your structures.

What Are Anchor Bolts and Why Are They Crucial in Construction?

Anchor bolts are essential fasteners used to attach structures or components to concrete. They play a vital role in load-bearing applications, ensuring that structures can withstand various stresses and loads. By providing a secure embedment into concrete, anchor bolts help distribute loads properly, reducing the risk of structural failure.

These bolts are inserted into drilled holes and secured with nuts and washers. The correct installation ensures that the bolt functions as intended, bearing axial loads and resisting shear forces. Without properly installed anchor bolts, the structural components could become loose, leading to potential hazards.

Understanding Mechanical Anchors: How Do They Work?

Mechanical anchors, such as wedge anchors, rely on physical expansion within a drilled hole to achieve holding power. When the nut is tightened, the anchor bolt expands against the sides of the hole, creating a secure fastening. This expansion is critical in transferring loads from the structural component to the concrete.

Mechanical anchors are suitable for various applications, especially where immediate load-bearing capacity is required. They ensure that the fastener is properly secured without the need for curing time, unlike chemical anchors.

Step-by-Step Guide to Installing Wedge Anchors

Installing wedge anchors requires precision to ensure structural integrity. Here’s a step-by-step guide:

-

Drill the Hole: Use a hammer drill with a carbide-tipped drill bit. The diameter of the hole must match the anchor bolt’s diameter. Ensure the hole depth accommodates the embedment length plus any additional space for debris.

-

Clean the Hole: Remove all dust and debris to ensure proper expansion of the anchor.

-

Insert the Anchor: Place the anchor bolt into the hole, ensuring it reaches the required embedment depth. The threads should protrude above the concrete surface to accommodate the nut and washer.

-

Tighten the Nut: Add the washer and nut. Tighten to the specified torque using a torque wrench to ensure the correct expansion and load-bearing capacity.

-

Verify Installation: Check that the minimum thread protrusion beyond the nut is achieved and that the nut is flush with the top of the bolt.

By following these steps, you ensure that the anchor is installed properly, reducing the risk of failure.

Common Mistakes to Avoid When Installing Anchors

Improper installation can lead to serious structural issues. Common mistakes include:

- Overlooking Hole Cleaning: Debris can prevent proper expansion, reducing holding capacity.

- Incorrect Hole Diameter: A hole that’s too large or small affects the anchor’s effectiveness.

- Insufficient Embedment: Not embedding the anchor bolt to the recommended depth can reduce load-bearing capacity.

- Excessive Torque: Over-tightening can cause the bolt to stretch or the concrete to crack.

Avoiding these mistakes ensures that the anchor bolts function correctly and maintain structural integrity.

How to Ensure Minimum Thread Protrusion Beyond the Nut

Minimum thread protrusion is essential for proper load distribution. To ensure this:

- Measure Accurately: Before installation, calculate the required bolt length, taking into account the thickness of the fixture, nut, and washer.

- Use the Right Bolt Length: The bolt must extend sufficiently to allow the nut to be tightened fully, with threads protruding beyond the top of the nut.

- Check After Installation: Visually inspect to confirm that the minimum number of threads protrude beyond the face of the nut.

Ensuring the correct protrusion prevents the nut from bottoming out on unthreaded sections and allows for proper tightening.

Choosing the Right Connector for Structural Stability

Connectors play a pivotal role in the overall stability of the structure. When selecting connectors:

- Consider Load Requirements: Choose connectors that can handle the anticipated axial and shear loads.

- Material Compatibility: Use connectors made of materials compatible with the anchor bolt, such as stainless steel for corrosive environments.

- Ensure Compliance: Verify that connectors meet industry standards and codes for your specific application.

Selecting suitable connectors ensures that the entire fastening system works cohesively.

The Role of Anchor Bolts in Load-Bearing Structures

Anchor bolts transfer loads from structures to the concrete foundation. They must:

- Bear Axial Loads: Support vertical forces without excessive stretch or deformation.

- Resist Shear Forces: Prevent lateral movement that could cause structural failure.

- Accommodate Thermal Expansion: Allow for slight movements due to temperature changes without compromising integrity.

Understanding their role helps specify the correct type and installation method for your project.

Mechanical vs. Chemical Anchors: Which Is Better?

Choosing between mechanical and chemical anchors depends on:

- Load Requirements: Chemical anchors may offer higher load capacities.

- Environmental Conditions: Wet or cracked concrete may favor chemical anchors.

- Installation Conditions: Mechanical anchors are preferable for immediate loading and simpler installations.

Both have unique advantages, and selection should be based on specific project needs.

Proper Torque Application in Anchor Bolt Installation

Applying the specified torque is crucial:

- Use a Torque Wrench: Ensure accuracy by using the correct tool.

- Follow Manufacturer’s Specifications: Over or under-tightening can reduce effectiveness.

- Avoid Excessive Rotation: Too much rotation can cause the bolt to fail or the concrete to crack.

Proper torque ensures the anchor bolt is neither too loose nor excessively tight.

Ensuring Compliance: Standards and Codes for Anchor Installation

Compliance with codes is mandatory:

- Understand Relevant Codes: Familiarize yourself with building codes like ACI and ICC guidelines.

- Use Certified Products: Ensure all components meet industry standards.

- Document Installation: Keep records for verification and inspections.

Compliance ensures safety and minimizes legal risks.

Conclusion: Best Practices for Anchor Bolt Installation

Proper installation of anchor bolts and nuts is essential for structural integrity. By understanding the importance of minimum thread protrusion, selecting the right connectors, and following proper installation techniques, you can ensure that your projects are safe and durable.

For high-quality anchor bolts and related products, consider exploring our Split Rock Friction Anchor and Mushroom Head Dome Nut offerings.

Key Takeaways:

- Proper Installation: Follow detailed steps to install anchor bolts correctly.

- Minimum Thread Protrusion: Ensure threads protrude beyond the nut for load distribution.

- Connector Selection: Choose compatible and compliant connectors.

- Torque Application: Use specified torque to avoid over-tightening or under-tightening.

- Compliance: Adhere to industry codes and standards for safety.

By adhering to these guidelines, you can enhance the safety, reliability, and longevity of your construction projects.

Post time: Dec-05-2024