Are you looking for a faster, more reliable, and efficient way to secure structures and stabilize slopes in your construction projects? Self-drilling anchor bolts are changing the game in construction and geotechnical engineering. This article dives deep into how these innovative bolts work, their benefits, and why they might be the perfect solution for your next project. Keep reading to discover how self-drilling anchor bolts can save you time, money, and ensure the stability you need.

1. What Exactly Are Self-Drilling Anchor Bolts and How Do They Drill?

Self-drilling anchor bolts are clever devices used in construction and engineering to securely anchor structures and stabilize the ground. Imagine a bolt that not only secures but also drills its own hole – that's the magic of a self-drilling anchor bolt! These specialized anchors combine drilling and anchoring into a single, efficient process. Instead of first drilling a hole and then inserting an anchor, these bolts do both simultaneously.

The secret lies in their design. A self-drilling anchor bolt is essentially a hollow steel bolt with a sacrificial drill bit attached at the end. This drill bit, made of tough material, is designed to penetrate through soil, gravel, and even solid rock as the bolt is rotated and pushed. The hollow centre of the bolt serves a crucial purpose. Once the bolt is drilled into the ground to the desired depth, grout – a special type of cement – is pumped through this hollow centre. This grout fills the space around the bolt, creating a strong bond with the surrounding soil or rock and providing robust anchorage. This drilling technology makes installation faster and more effective, especially in challenging ground conditions.

2. Why Choose Self-Drilling Anchor Bolts for Your Construction Projects?

In the fast-paced world of construction, time and efficiency are everything. Self-drilling anchor bolts offer significant advantages that can streamline your construction projects. Traditional anchor installation is a two-step process: first drill, then insert. This takes time and resources. Self-drilling anchor bolts combine these steps, saving valuable time and manpower. This is especially beneficial in large construction projects where many anchors are needed.

Think about sites with unstable soils or overburden. Traditional drilling methods might struggle, causing delays and extra costs. Self-drilling anchors are designed to handle these challenging conditions. The casing effect of the hollow bolt prevents the hole from collapse during drilling and grouting, ensuring a stable and reliable anchor. Furthermore, the precise drilling action minimizes disturbance to the surrounding ground, which is crucial for maintaining stability, especially in sensitive areas or near existing structures. For projects where speed, reliability, and minimal disruption are key, self-drilling anchor bolts are an excellent choice.

3. In What Construction Application Areas Are Self-Drilling Anchor Bolts Commonly Used?

Self-drilling anchor bolts are incredibly versatile and find applications in a wide range of construction and geotechnical engineering scenarios. One of their most important uses is in slope stabilization. Imagine a steep slope that's at risk of collapse. Self-drilling anchors can be drilled into the ground to stabilize the slope, preventing landslides and ensuring safety. This is vital for road and railway construction, as well as for protecting buildings built on or near slopes.

They are also commonly used in tunneling and mining. In these underground environments, ground support is paramount. Self-drilling anchors provide reliable support to tunnel and mine walls, preventing collapse and creating safer working conditions. In building foundations, especially in areas with poor soil conditions, these anchors can be used to provide deep foundation support, transferring the load of the structure to stronger, deeper layers of the ground. They are also used for retaining walls, bridges, and even temporary earth retention in excavation sites. From large-scale infrastructure projects to smaller stabilize walls applications, self-drilling anchor bolts offer a robust and adaptable solution.

4. What Are the Key Components of a Self-Drilling Anchor Bolt System?

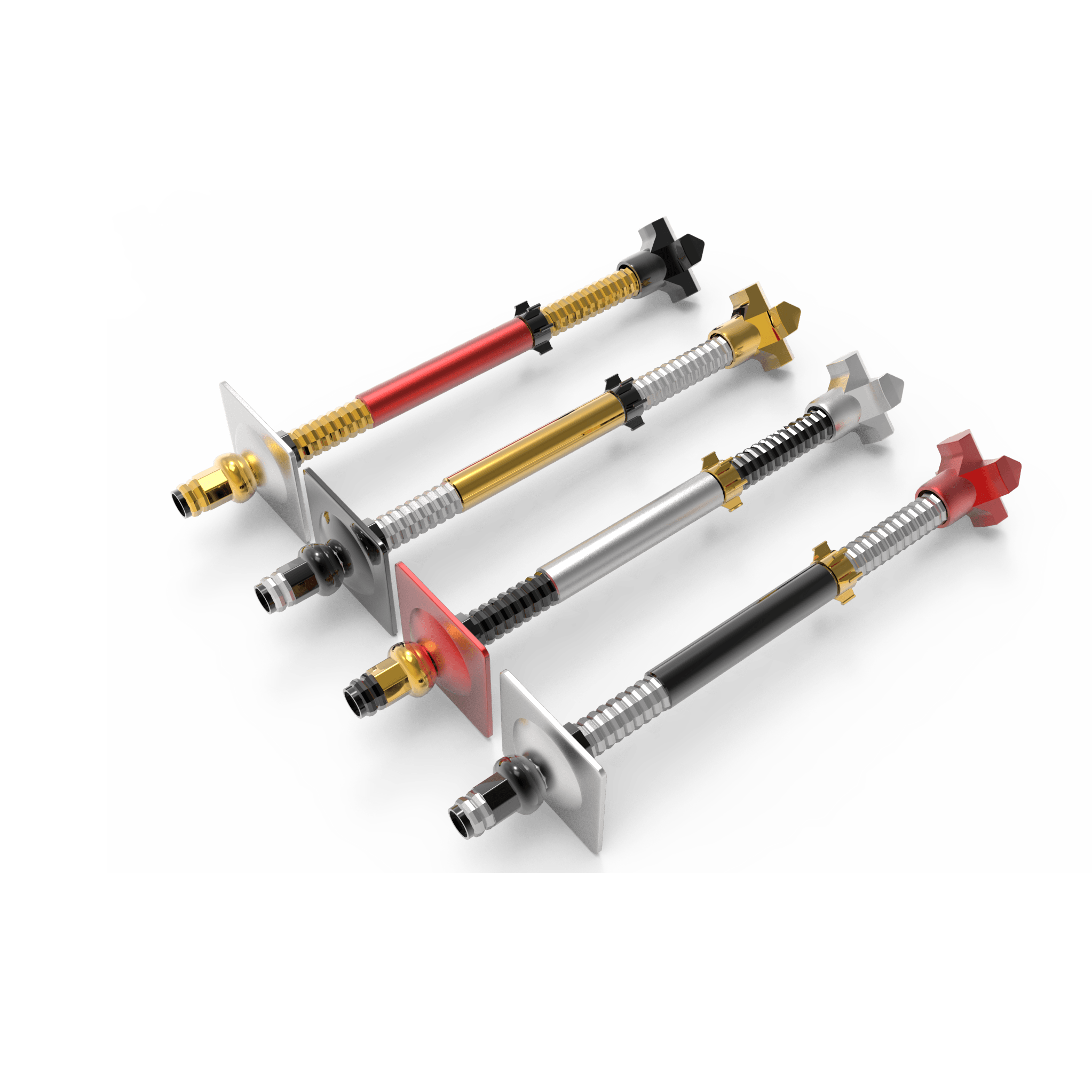

A self-drilling anchor bolt system isn't just a single bolt; it's a combination of components working together to provide reliable anchorage. The core element is, of course, the hollow anchor bolt itself, typically made of high-strength steel. This bolt is threaded internally and externally to allow for attachment of other components. At the leading end is the sacrificial drill bit. This drill bit is designed to be robust enough to penetrate various ground conditions, and it's considered "sacrificial" because it may wear out during drilling but is usually left in place after installation.

An anchor sleeve, sometimes called a casing sleeve, is often used to help guide the bolt during drilling and provide extra stability at the surface. A coupling or adapter is used to attach the bolt to the drilling equipment. Once the bolt is in place, various accessories are used to complete the anchorage. These include anchor nuts to tension the bolt, washers and anchor plates to distribute the load, and centralizers to keep the bolt centred in the drilled hole for optimal grouting. Finally, grout is the essential binding agent that fills the hollow bolt and the surrounding space, creating a strong, permanent anchor. Each component plays a vital role in the overall performance and stability of the self-drilling anchor system.

5. How Do Self-Drilling Anchor Bolts Compare to Traditional Anchor Bolts in Construction?

When choosing anchor solutions for construction, it's important to understand the differences between self-drilling anchor bolts and traditional anchor bolts. Traditional anchor bolts typically require a separate drilling step before installation. This means drilling a hole using conventional drilling technology, then inserting and setting the anchor into the pre-drilled hole. This two-step process can be time-consuming and less efficient, especially in challenging ground conditions.

Self-drilling anchor bolts, as we've discussed, combine drilling and installation into one operation. This saves time and reduces manpower. In terms of performance, both types of anchors can provide strong anchorage, but self-drilling anchors often excel in unstable soils and overburden conditions where pre-drilled holes might collapse. The casing effect of the hollow bolt in self-drilling systems provides better hole stability and ensures proper grouting. While traditional anchor bolts might be suitable for simpler projects in stable ground, self-drilling anchor bolts offer a more robust and efficient solution for a wider range of construction challenges, particularly where speed and ground stability are critical. Consider using shank adapters with your drill for optimal performance with both types of bolts.

6. What Are the Top Advantages of Using Self-Drilling Anchor Bolts for Slope Stabilization and More?

The benefits of self-drilling anchor bolts extend across various aspects of construction and geotechnical work. For slope stabilization, their speed of installation is a major advantage. Quickly deploying anchors in unstable slopes can be crucial in preventing landslides and ensuring safety, especially in emergency situations. The ability to drill and grout simultaneously is another key benefit. This ensures that the hole is immediately supported, minimizing ground disturbance and maximizing stability. The hollow system allows for thorough grouting from the bottom up, creating a strong and consistent bond along the entire length of the anchor.

Self-drilling anchors are also highly adaptable to different ground conditions. They can penetrate through soil, gravel, and rock, making them suitable for a wide range of sites. Compared to traditional methods, they often require shallower holes for the same level of anchorage, which can further reduce installation time and material costs. From an environmental perspective, the reduced drilling time and ground disturbance can lower the overall environmental impact of construction projects. For projects focused on slope stabilization, foundation support, or ground improvement, self-drilling anchor bolts offer a powerful combination of efficiency, reliability, and adaptability.

7. How Do You Select the Right Self-Drilling Anchor Bolt for Each Specific Project?

Selecting the right self-drilling anchor bolt is crucial for ensuring the success and stability of your construction project. Several factors need careful consideration. First, understand the ground conditions. Is it soil, gravel, solid rock, or a mix? The ground type will influence the choice of drill bit and the required bolt strength. Consider the load-bearing requirements. How much weight will the anchor need to support? This will determine the diameter and material of the bolt. Factor in the environmental conditions. Will the anchors be exposed to corrosion? If so, consider using bolts with protective coatings or materials like stainless steel.

Project duration is also important. For temporary anchors, lower specification options might suffice, while permanent anchors, like those for building foundations, will require high-quality, durable bolts designed for long-term performance. Think about the installation equipment available. Ensure that your drilling equipment is compatible with the chosen anchor system. Finally, always consider safety standards and certifications. Choose anchor bolts that comply with relevant international safety standards to ensure reliability and safety. By carefully evaluating these factors, you can browse and select the types of anchors that are perfectly suitable for your specific project needs.

You can browse our selection of high-quality anchor bolts to find the perfect fit for your project.

8. Are Self-Drilling Anchor Bolts Suitable for Different Soil and Rock Types?

One of the great strengths of self-drilling anchor bolts is their versatility in handling various ground conditions. They are designed to be effective in a range of soil and rock types, making them highly adaptable for diverse construction sites. In soil and gravel, the sacrificial drill bit efficiently cuts through the material, and the casing effect of the hollow bolt prevents hole collapse in unstable soils. For harder ground like solid rock, specialized drill bits made of tungsten carbide or other hard materials are used to penetrate effectively.

The design of self-drilling anchor bolts allows for modifications to suit different ground conditions. For example, for very loose soil, larger diameter bolts or specialized grouting techniques might be used to improve anchorage. In fractured rock, grout can fill the fractures, creating a stronger bond. While self-drilling anchors are highly adaptable, it's essential to conduct site investigations to understand the specific ground conditions and selecting the right drill bit and bolt type accordingly. This ensures optimal performance and stability regardless of whether you are working in soft soil, dense gravel, or hard rock.

9. What Are the Key Installation Steps for Self-Drilling Anchor Bolts?

Installing self-drilling anchor bolts is a streamlined process, but following the correct steps is crucial for ensuring proper anchorage and stability. The first step is site preparation and marking out the anchor locations according to the engineering design. Next, attach the sacrificial drill bit to the hollow anchor bolt and connect the bolt to the rotary drilling equipment using a coupling or adapter.

Begin drilling by applying both rotation and thrust to the bolt. The drill bit will penetrate the ground, and the bolt will advance simultaneously. Continue drilling until the anchor reaches the designed depth. Once the desired depth is reached, stop drilling and prepare for grouting. Connect the grout pump to the hollow bolt and pump grout through the bolt until it flows out at the surface, ensuring that the entire hole is filled from the bottom up. Allow the grout to cure according to the manufacturer's instructions. Finally, tension the anchor bolt using an anchor nut and washer to the specified torque, and attach any required anchor plates or other accessories. Proper installation is key to maximizing the performance and durability of self-drilling anchor bolts.

10. Where Can You Browse High-Quality Self-Drilling Anchor Bolt Solutions for Your Needs?

Finding a reliable supplier of high-quality self-drilling anchor bolt systems is essential for your construction projects. As a factory with 7 production lines based in China, we, at Self drilling anchor tools factory, specialize in providing top-notch Self-Drilling Anchor Systems and Drilling Tools. We offer a comprehensive product range, including anchor bars, anchor bits, anchor nuts, anchor couplers, anchor plates, centralizers, and more. Our products are manufactured using high-quality materials, ensuring they are reliable, durable, and compliant with international safety standards.

We cater to B2B customers like construction companies, mining companies, tunneling contractors, and geotechnical engineering firms in the USA, North America, Europe, and Australia. We understand the needs of customers like Mark Davis, who prioritize quality and competitive pricing. To browse our full range of self-drilling anchor bolt solutions and drilling equipment, please visit our website Self drilling anchor tools factory. You can explore our product pages like Rock Drilling Bits, Tapered drill pipe, and Shank adapters to find detailed specifications and images. We are committed to providing efficient communication, timely shipments, and genuine certifications to meet and exceed your expectations. Contact us today to discuss your project requirements and discover how our self-drilling anchor solutions can benefit you.

Key Takeaways: Self-Drilling Anchor Bolts for Construction

- Efficiency: Self-drilling anchor bolts combine drilling and installation, saving time and manpower.

- Versatility: Suitable for a wide range of ground conditions, from soil to solid rock.

- Stability: Provides excellent ground support and stability, especially in unstable soils and overburden.

- Applications: Used in slope stabilization, building foundations, tunneling, mining, and more.

- Comprehensive System: Consists of bolts, drill bits, couplers, anchor plates, grout, and other components.

- Quality is Key: Choose high-quality anchor bolts from reliable suppliers for optimal performance and safety.

- Proper Installation: Follow correct installation steps to ensure effective anchorage.

- Browse Solutions: Explore reputable suppliers like Self drilling anchor tools factory to find the right self-drilling anchor solutions for your projects.

By understanding the benefits and applications of self-drilling anchor bolts, you can make informed decisions to improve the efficiency, reliability, and safety of your construction and geotechnical projects.

Post time: 2 月-06-2025