Hanging items on hollow doors can feel tricky. Unlike solid walls, the thin surfaces offer little material for a standard screw to grip. This is where specialized fixings come in. This guide dives deep into hollow door fixings, specifically focusing on the popular Plasplugs hollow door fixings 6mm x 23mm 20 pack. We’ll explore how they work, why they are often the ideal item for lightweight tasks, and how to use them correctly, ensuring you get a secure holding every time. Whether you’re putting up coat hooks or small shelves, understanding the right anchor makes all the difference, preventing damage and ensuring your fixtures stay put. This article is worth reading because it demystifies the process and helps you choose and use the correct product confidently.

What Exactly Are Hollow Door Fixings?

Hollow door fixings are specialized fasteners designed specifically for use in doors that aren’t solid wood all the way through. Most interior doors today are constructed with a wooden frame around the perimeter and internal support structures (like cardboard honeycomb or timber spars), covered by thin surface panels, often made of hardboard, MDF, or plywood. This construction leaves significant voids or hollow spaces inside. A standard screw or basic wall plug driven into this thin surface won’t find enough material to create a strong, lasting grip.

These specialized fixings, often called hollow door anchors, are engineered to overcome this challenge. They typically work by expanding or bracing themselves against the inside surface of the door’s skin once inserted through a drilled hole. This creates a much larger contact area and distributes the load, providing a far more secure anchor point than a simple screw could achieve on its own. Think of it like spreading the weight – essential when dealing with a thin wall or surface.

The market offers various types, but the core principle remains: creating a stable anchor point within a void. Understanding this basic mechanism is key to appreciating why a specific product like the Plasplugs hollow door fixing is often recommended for these applications. They are distinct from fixings designed for solid brick or concrete, or even standard hollow wall applications like plasterboard, though some overlap exists.

Why Do Standard Wall Plugs Fail in Hollow Doors?

Standard wall plugs, like the common ribbed plastic ones you might use in drywall or masonry, rely on friction and expansion within a solid material. When you drill a hole and insert the plug, tightening the screw causes the plug to expand outwards, pressing firmly against the sides of the drilled hole. This friction is what provides the holding power. This method works brilliantly in solid materials where there’s plenty of surrounding substance for the plug to push against.

However, a hollow door presents a completely different scenario. The surface skin might only be 3-6mm thick. When you drill a hole and insert a standard wall plug, there’s simply not enough material depth for the plug to expand into effectively. The thin skin offers minimal resistance, and the void behind it means there’s nothing solid for the expanding plug to grip against. Tightening the screw might just pull the plug through the hole, enlarge the hole, or provide a very weak fixing that fails under minimal load.

This lack of solid material is precisely why specialized hollow door fixings were developed. They don’t rely solely on friction against the sides of the hole. Instead, they use mechanical means – wings, toggles, or collapsing bodies – to brace against the inaccessible rear side of the thin door skin. This fundamental difference in mechanism makes them the appropriate option for achieving security in hollow structures. Using the wrong product here inevitably leads to frustration and potential damage.

Introducing the Plasplugs Hollow Door Fixings: What Makes Them Special?

Plasplugs is a well-known brand in the fixings market, particularly for DIY applications. Their hollow door fixings are a popular product specifically engineered for the challenges we’ve discussed. What makes them stand out is their simple yet effective design, tailored for light to medium-duty applications on materials like hardboard, MDF, plywood, and similar thin-skinned structures often found in modern interior doors. They fall under the category of Plasplugs specialised fixings.

The design typically involves a plastic body that collapses or bunches up behind the door skin as the screw is tightened. This collapsed section forms a broad shoulder or knot, effectively clamping the fixing against the inner surface. This prevents pull-through and spreads the load, creating a reliable anchor point. They are generally easy to install, requiring only a pre-drilled hole of the correct size.

Compared to some other hollow wall anchors, Plasplugs hollow door fixings are often more discreet and require a smaller installation hole, minimizing damage to the door surface. They are particularly suited for the very thin materials common in hollow door construction, where larger, more aggressive fixings might risk cracking or damaging the fragile skin. Their simplicity and effectiveness for their intended purpose make them a go-to item for many homeowners.

Unpacking the Details: The Plasplugs 6mm x 23mm 20 Pack

When you purchase a pack like the Plasplugs hollow door fixings 6mm x 23mm 20 pack, you’re getting a specific size and quantity designed for common household tasks. Let’s break down what those numbers mean:

- 6mm: This refers to the diameter of the drill bit required to create the installation hole. Using the correct size drill bit is crucial for the fixing to work properly. Too small, and you can’t insert the anchor; too large, and it won’t grip effectively.

- 23mm: This is the length of the fixing itself. This length is designed to work within the typical void depth found in standard hollow doors and accommodate common screw lengths associated with household fixtures like hooks or brackets.

- 20 Pack: This simply indicates the quantity of fixings included in the pack. This quantity is usually sufficient for several small projects around the house.

This specific product (door fixings 6mm x 23mm) is often bundled this way (fixings 6mm x 23mm 20) for convenience and value. The pack usually contains only the plastic fixing bodies; the screw required to activate them is often determined by the item you are attaching, though recommendations for screw size (gauge) are typically provided. Always check the packaging for the recommended screw specifications to ensure optimal performance and a secure fit. Finding this exact item is common in hardware stores or online retailers like Screwfix.

How Does the Anchor Mechanism Work in a Hollow Space?

The genius of the Plasplugs hollow door fixing lies in its simple mechanical action within the void behind the door skin. Unlike solid wall fixings, it doesn’t rely on expanding into the material. Instead, it uses the void to its advantage. Here’s the typical process:

- Insertion: After drilling the correct size hole (e.g., 6mm), the plastic anchor body is gently pushed through the hole until its collar or flange is flush with the door surface.

- Screw Engagement: The item you want to hang (like a coat hook) is positioned over the anchor, and the appropriate size screw is inserted through the item and into the anchor.

- Activation: As you begin to tighten the screw, it draws the rear part of the anchor body towards the inner surface of the door skin.

- Collapsing & Clamping: The clever design causes the anchor body within the hollow space to collapse concertina-style or bunch up. This deformed section forms a solid knot or shoulder behind the thin wall.

- Secure Anchor: This knot braces against the inside of the door skin, effectively clamping the fixing in place. The screw continues to tighten, securing your fixture firmly. The load is now distributed over a wider area on the inside, providing a much stronger holding than a screw alone could achieve.

This method provides good security for lightweight items on notoriously difficult hollow door surfaces. It’s a reliable system when used within its load limits.

Choosing the Right Size: Is 6mm x 23mm Always the Best Option?

The Plasplugs hollow door fixings 6mm x 23mm are a very common and versatile size, but whether they are always the best option depends on a few factors:

- Fixture Weight: The 6mm size is generally intended for light to medium-light duty applications – think coat hooks, small picture frames, lightweight shelves, or towel rings. If you plan to hang something heavier, you might need a more robust fixing solution, potentially a different type of hollow wall anchor altogether or even reinforcing the door structure itself.

- Door Skin Thickness: While designed for standard hollow door skins (typically 3-6mm), extremely thin or unusually thick skins might affect performance. The 23mm length is generally suitable for common door constructions.

- Screw Size: The fixing is designed to work with a specific range of screw gauges (thicknesses). Using a screw that is too thin won’t activate the collapsing mechanism properly, while a screw that is too thick could damage the plastic anchor. Always refer to the manufacturer’s recommendations for the compatible screw size or gauge.

- Material: While ideal for the typical hardboard or MDF skins of hollow doors, performance might vary slightly in very soft plywood or brittle plastic surfaces.

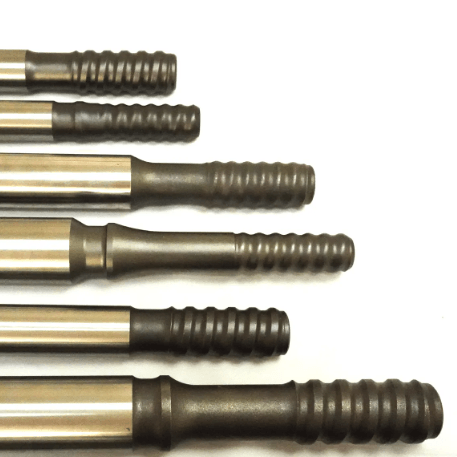

So, while the 6mm x 23mm product is a fantastic general-purpose hollow door fixing, it’s essential to assess your specific needs. For significantly heavier loads, consider larger hollow wall anchors like toggler bolts or butterfly fixings, which offer a wider grip range and higher load capacity, although they usually require a larger installation hole. Always err on the side of caution; if in doubt, choose a stronger fixing method. Remember, even in heavy industry, selecting the right anchor, like choosing between different Rock Drilling Bits for specific rock types, is crucial for performance and safety.

Step-by-Step Installation Guide for Plasplugs Hollow Door Fixings

Installing Plasplugs hollow door fixings is straightforward if you follow the steps carefully. Here’s a simple guide:

- Mark the Spot: Decide exactly where you want to hang your item on the hollow door. Use a pencil to mark the precise location for the fixing.

- Check for Obstructions: Gently tap the area. A very dull thud might indicate a solid timber frame or internal support just behind the skin. Try to position your fixing in a truly hollow section (which usually sounds more resonant). Avoid drilling right at the edge of the door where the solid wood frame is located unless you plan to use a wood screw.

- Drill the Hole: Select the correct size drill bit as specified on the pack (e.g., 6mm for the 6mm x 23mm fixing). Drill a clean, perpendicular hole through the door skin at your marked spot. Be careful not to push too hard once the bit breaks through the first skin, to avoid damaging the opposite side if the door is very thin.

- Insert the Fixing: Take one plastic anchor from the pack. Gently push the pointed end into the drilled hole. You may need to wiggle it slightly. Push it in until the collar or flange sits flush against the door surface. Do not force it excessively.

- Position Your Fixture: Place the item you want to hang (e.g., the bracket, hook) over the inserted anchor, aligning its mounting hole with the center of the anchor.

- Insert and Tighten the Screw: Select the appropriate size and length screw (check the fixing packaging for recommendations). Insert the screw through your fixture and into the anchor. Begin tightening the screw using a screwdriver. You should feel resistance as the screw engages and starts to pull the back of the anchor, causing it to collapse and grip behind the door skin.

- Secure Firmly: Continue tightening until the fixture is held securely against the door. Do not overtighten, as this could strip the anchor’s internal thread or damage the door skin. The fixing should feel solid and stable.

Following these steps ensures the hollow door fixing works as intended, providing a reliable anchor point.

Beyond Doors: Where Else Can You Use These Fixings?

While specifically marketed as hollow door fixings, the design principles of the Plasplugs 6mm x 23mm anchor make it potentially useful in other situations involving thin, hollow materials where a strong fixing is needed for light loads. Their effectiveness stems from their ability to create a brace behind a thin sheet material.

Consider these potential applications:

- Thin Plywood Panels: Walls or structures made from thin plywood (e.g., 4-6mm thick) often found in sheds, workshops, or some furniture construction.

- Fibreglass: Certain applications in boat and caravan interiors might involve fixing items to plywood and fibreglass composite panels. The ability to grip behind the thin skin is advantageous here.

- Thin Skin Partitions: Some temporary or lightweight internal office partitions might use thin board materials over a frame.

- Hardboard or Masonite: Fixing items to cabinets, backing boards, or display units made from hardboard.

- Certain Plastic Panels: Depending on the rigidity and thickness of the plastic, these fixings might offer a better solution than a simple self-tapping screw.

However, it’s crucial to remember their limitations. They are designed for lightweight applications. They are generally unsuitable for standard plasterboard/drywall (hollow wall), as dedicated drywall anchors (like toggler bolts or self-drilling metal anchors) provide superior load-bearing capacity and are designed for that material’s specific properties. They are also not intended for exterior use or situations with heavy vibration or dynamic loads. Always assess the material and the load before using these versatile, but light-duty, fixings.

Comparing Options: Plasplugs vs. Toggler and Butterfly Anchors

When faced with a hollow wall or hollow door, Plasplugs hollow door fixings are just one option. Understanding the alternatives helps you choose the best product for your needs. Let’s compare them with two common heavier-duty types: Toggler bolts and Butterfly anchors.

| Feature | Plasplugs Hollow Door Fixing (e.g., 6mm) | Toggler Bolt (e.g., SnapToggle) | Butterfly Anchor (Metal Toggle Wings) |

|---|---|---|---|

| Primary Use | Very thin hollow doors, plywood | Plasterboard, thicker hollow walls | Plasterboard, hollow walls, ceilings |

| Mechanism | Collapsing plastic body behind skin | Metal channel flips behind wall | Metal wings spring open behind wall |

| Load Capacity | Light to Medium-Light | Medium to Heavy Duty | Medium to Heavy Duty |

| Installation | Simple, small hole (e.g., 6mm) | Requires larger hole | Requires larger hole |

| Material | Plastic | Metal channel, plastic straps | Metal wings and screw |

| Reusability | Generally single-use | Bolt can be removed/reinserted | Bolt can be removed/reinserted |

| Advantages | Small hole, discreet, easy install | Very high strength, reliable | High strength, common type |

| Disadvantages | Lower load capacity | Larger hole needed, more complex | Larger hole needed, wings can snag |

Key Differences:

- Strength: Toggler and Butterfly anchors, typically made of steel, offer significantly higher load-bearing capacity, suitable for heavier items like shelves, mirrors, or curtain rails on standard plasterboard walls. The Plasplugs plastic design is optimized for lighter tasks on thinner materials like hollow door skins.

- Installation Hole Size: The Plasplugs require a much smaller hole (6mm), minimizing surface damage, which is often preferred on finished doors. Toggler and Butterfly types need larger holes (often 13mm or more) to allow the toggle mechanism to pass through.

- Application: While Togglers and Butterfly anchors could potentially be used on a hollow door, their larger size and higher clamping force might risk damaging the thin door skin. The Plasplugs product is specifically designed for this delicate application.

In essence, choose Plasplugs hollow door fixings for light duties on thin surfaces like hollow doors. Opt for Toggler or Butterfly anchors when you need heavy duty security on standard plasterboard or thicker hollow wall constructions. Selecting the right type of anchor is fundamental, just as choosing the correct Nut and bolt combination is critical in structural engineering.

Key Considerations: Price, Pack Size, and Delivery

When purchasing hollow door fixings, especially items like the Plasplugs hollow door fixings 6mm x 23mm 20 pack, practical factors like price, quantity, and availability come into play.

- Price: Plasplugs fixings are generally very affordable, especially when bought in multi-packs. The price per item is typically low, making them a cost-effective solution for multiple small jobs around the house. Comparing the price of a pack versus buying individual fixings (if available) usually shows the pack offers better value. However, always compare prices across different retailers.

- Pack Size: The 20 pack (6mm x 23mm 20 pack) is a common offering, providing a good balance between having enough fixings for several tasks without excessive surplus. Consider how many fixing points you anticipate needing. Buying a larger pack might offer a lower per-item price, but only if you’re likely to use them. Smaller packs might also be available for single, small jobs.

- Delivery: Availability is usually excellent in major hardware stores and online. When ordering online, factor in delivery costs and times. If you need the fixings urgently for a project, check delivery speeds or consider purchasing locally. Some retailers might offer free delivery over a certain spend, which could influence your decision to bundle purchases. For businesses like mine dealing with large B2B orders of specialized equipment like Self drilling anchor tools, logistics and reliable delivery are paramount, often involving international shipping and careful planning. While buying a small pack of Plasplugs is simpler, the principle of timely delivery remains important for any project.

Always ensure you are buying the correct product (hollow door fixings vs. normal wall plugs) and the right size (6mm x 23mm if that’s what you need) before finalizing your purchase based on price and delivery options.

Achieving Superior Grip: Tips for a Secure and Lasting Fix

Even with the right product like Plasplugs hollow door fixings, proper technique ensures maximum security and longevity. Here are some tips for achieving a superior grip:

- Use the Right Drill Bit: Precision is key. Use a sharp 6mm drill bit for the 6mm x 23mm fixings. An old, dull bit or the wrong size can create a messy or incorrectly sized hole, compromising the anchor’s performance.

- Clean the Hole: After drilling, ensure the hole is free of dust and debris. A cleaner hole allows the fixing’s collar to sit flush against the surface.

- Don’t Force the Anchor: Insert the plastic anchor gently. If it requires excessive force, the hole might be too small, or you might have hit an unexpected obstruction.

- Choose the Correct Screw: Use the screw gauge and length recommended by Plasplugs. A screw that’s too thin won’t expand the anchor correctly; one that’s too thick can damage it. The screw should be long enough to pass through your fixture and fully engage the collapsing mechanism of the anchor.

- Tighten Appropriately: Tighten the screw steadily until the fixture is snug against the door. Feel the resistance as the anchor collapses and grips. Avoid the temptation to overtighten – this can strip the plastic thread or even crack the door skin around the hole, especially on fragile surfaces.

- Respect Load Limits: These are light-duty fixings. Don’t use them for heavy mirrors, shelves loaded with books, or anything safety-critical like grab bars. Understand the limits of the product and the hollow door itself.

- Consider Pilot Holes (Optional): For very delicate surfaces, drilling a smaller pilot hole first, then widening it to 6mm, can sometimes result in a cleaner finish.

By paying attention to these details, you ensure the Plasplugs hollow door fixing performs optimally, providing a surprisingly strong and secure anchor point for its intended applications, keeping your items safely attached to your hollow door.

Key Takeaways for Hollow Door Fixings

- Specialized Need: Hollow doors require specific fixings like Plasplugs hollow door fixings because standard plugs won’t grip securely in the thin skin and void.

- Mechanism: These fixings work by collapsing or bunching behind the door skin when a screw is tightened, creating a secure anchor.

- Common Size: The Plasplugs 6mm x 23mm 20 pack is a popular product for light-duty tasks, requiring a 6mm drill hole.

- Correct Installation: Use the right drill bit size, insert the anchor flush, use the recommended screw gauge, and tighten carefully without overtightening.

- Light Duty: These plastic fixings are ideal for lightweight items like coat hooks or small pictures on hollow doors, thin skin partitions, or plywood.

- Alternatives: For heavier loads or standard plasterboard walls, consider stronger hollow wall anchors like Toggler bolts or Butterfly fixings, though they require larger holes.

- Check Details: Always verify the product specifications, recommended screw size, and assess the load before installation. Consider price, pack size, and delivery when purchasing.

By understanding these points, you can confidently tackle projects involving hollow doors and achieve a safe, secure result every time.

Post time: 4 月-21-2025