Connecting rods effectively is crucial in construction and engineering projects. Rod couplers play a significant role in extending threaded rods, offering a simple and practical solution for various applications. In this article, we'll delve into the world of rod couplers, exploring their uses, types, and how they help professionals in the field. Whether you're a seasoned engineer or new to the concept, this guide provides valuable insights into rod coupling techniques.

Alt text: Rod Couplers in Action

What Is a Rod Coupler and How Does It Work?

A rod coupler is a mechanical device used to connect two threaded rods together, effectively extending their length. It serves as a link between rods, allowing for flexibility and adaptability in various projects. Rod couplers come in different sizes and are manufactured to match specific threaded rod dimensions.

The coupler's design ensures a strong and secure connection, providing the necessary support for structures. By using a rod coupler, professionals can extend rods without compromising the integrity of the joint, which is essential in construction and engineering applications.

Why Use Threaded Rods in Construction and Engineering?

Threaded rods are versatile components used across multiple industries. They offer:

- Strength and Durability: Made from materials like steel, they provide robust support.

- Flexibility: Easy to extend or shorten based on project needs.

- Compatibility: They work with various nuts and couplers for customized solutions.

Using threaded rods allows for simple adjustments and modifications, making them ideal for projects that may require changes during the construction process.

How to Extend a Rod Using Couplers

Extending a rod using a coupler is a straightforward process. Here's a step-by-step guide:

- Select the Right Coupler: Ensure the coupler matches the thread size of your rod.

- Prepare the Rod Ends: Clean and check for any damage.

- Thread the Coupler onto One Rod: Twist it until it's securely in place.

- Connect the Second Rod: Thread the other rod into the opposite end of the coupler.

- Tighten the Connection: Use appropriate tools to ensure a firm hold.

This method provides a strong and safe connection without the need for welding or other permanent joining techniques.

Types of Rod Couplers Available

Rod couplers come in various types to suit different applications:

- Standard Couplers: Basic connectors for similar rod sizes.

- Reducing Couplers: Used to connect rods of different diameters.

- Positioning Couplers: Allow for precise alignment and adjustment.

Understanding the options helps in selecting the right coupler for your specific needs, ensuring efficiency and reliability in your project.

Alt text: Different Types of Rod Couplers

The Role of Nuts in Rod Coupling

Nuts play a vital role in rod coupling:

- Locking Mechanism: They lock the rods and couplers in place.

- Adjustability: Allow for fine-tuning the tension and length.

- Support: Provide additional strength to the joint.

Using the appropriate nuts, such as coupler nuts, ensures that the connection remains secure under various loads and conditions.

Simple Steps to Connect Threaded Rods Together

Connecting threaded rods can be achieved through:

- Using Couplers: As described earlier, couplers provide a simple way to connect rods.

- Welding: For permanent connections, welding the rods together is an option, though it requires professional skills.

- Using Threaded Connectors: Specialized connectors that provide a secure link without additional tools.

The choice depends on the specific requirements of the project and whether a permanent or adjustable connection is needed.

Tools Required for Installing Rod Couplers

To install rod couplers, you might need:

- Wrenches: For tightening nuts and couplers.

- Thread Sealants: Such as Loctite, to prevent connections from becoming loose.

- Measuring Tools: To ensure accurate alignment and length.

Having the right tools ensures a smooth installation process and a strong connection.

Understanding Thread Sizes and Standards

Threads come in various sizes and standards:

- Metric and Imperial: Different measurement systems.

- Coarse and Fine Threads: Affect the strength and adjustability.

- Standardization: Ensures compatibility between rods, nuts, and couplers.

Knowing the thread specifications is essential to select components that fit together seamlessly.

Welding vs. Coupling: Which Method to Choose?

When deciding between welding and coupling:

- Welding:

- Permanent solution.

- Requires professional skills and equipment.

- Not easily adjustable.

- Coupling:

- Simple and quick.

- Adjustable and reusable.

- Doesn't require specialized skills.

For projects that may require future adjustments or where ease of installation is a priority, using rod couplers is often the preferred solution.

Common Applications of Rod Couplers in Various Industries

Rod couplers are used in:

- Construction: For building frameworks and extending supports.

- Mining and Tunneling: Connecting drill rods and supports.

- Geotechnical Engineering: Extending anchors and reinforcement rods.

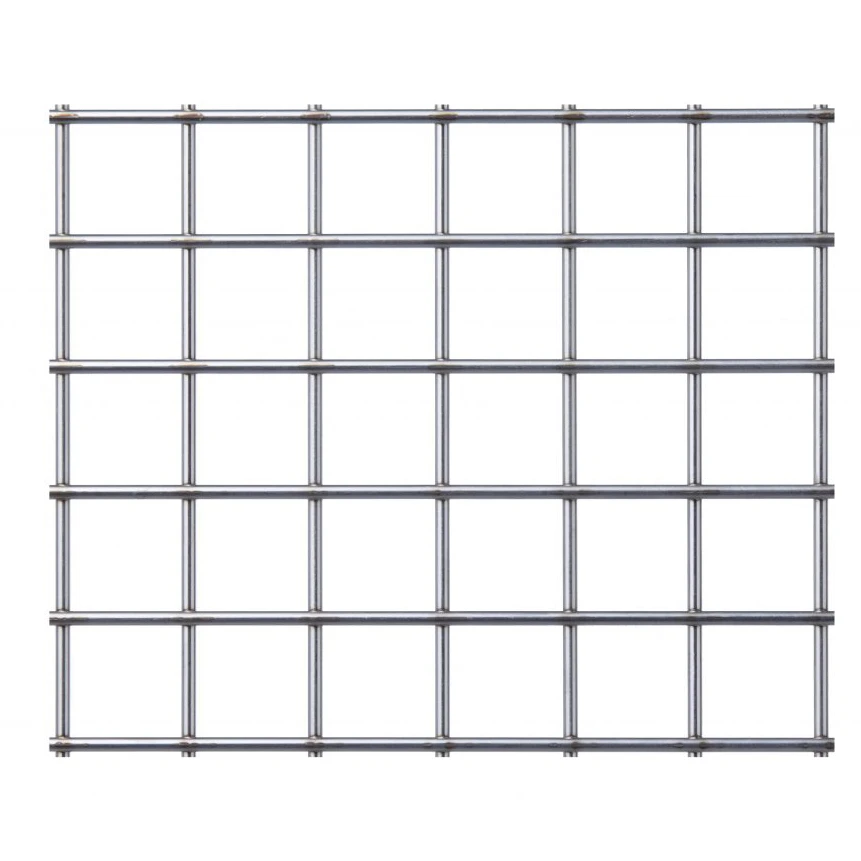

Companies like Mine welding wire support mesh offer specialized products that utilize rod couplers for enhanced performance.

Alt text: Rod Couplers in Construction

Tips for Selecting the Right Rod Coupler

When choosing a rod coupler:

- Check the Thread Size: Ensure compatibility.

- Consider the Material: Match with the rods for consistency.

- Evaluate the Load Requirements: Select a coupler that can handle the expected stress.

- Consult Professionals: When in doubt, seek guidance from experts.

Selecting the right coupler contributes to the overall safety and effectiveness of the project.

Conclusion

Rod couplers are indispensable tools in modern construction and engineering, providing a practical way to extend threaded rods and adjust to the needs of a project. Understanding how to select and install them ensures that structures are built with strength and reliability.

Key Takeaways:

- Rod Couplers connect threaded rods to extend their length.

- Using couplers is a simple and adjustable alternative to welding.

- Nuts and thread sealants like Loctite enhance the connection's security.

- Selecting the right coupler requires understanding thread sizes and project requirements.

- Tools and proper installation techniques ensure a strong and safe connection.

For more information on related products, you might visit Coupling and Threaded Steel Anchor for specialized solutions.

Post time: 12 月-08-2024