In the challenging world of underground mining, ensuring the stability of rock formations is crucial for safety and efficiency. Split set bolts, also known as friction bolts, have become indispensable tools in providing reliable ground support. This article explores what split set bolts are, how they work, and why they are vital in underground mining operations. Whether you're a seasoned professional or new to the field, you'll discover valuable insights into this essential technology.

What Is a Split Set Bolt?

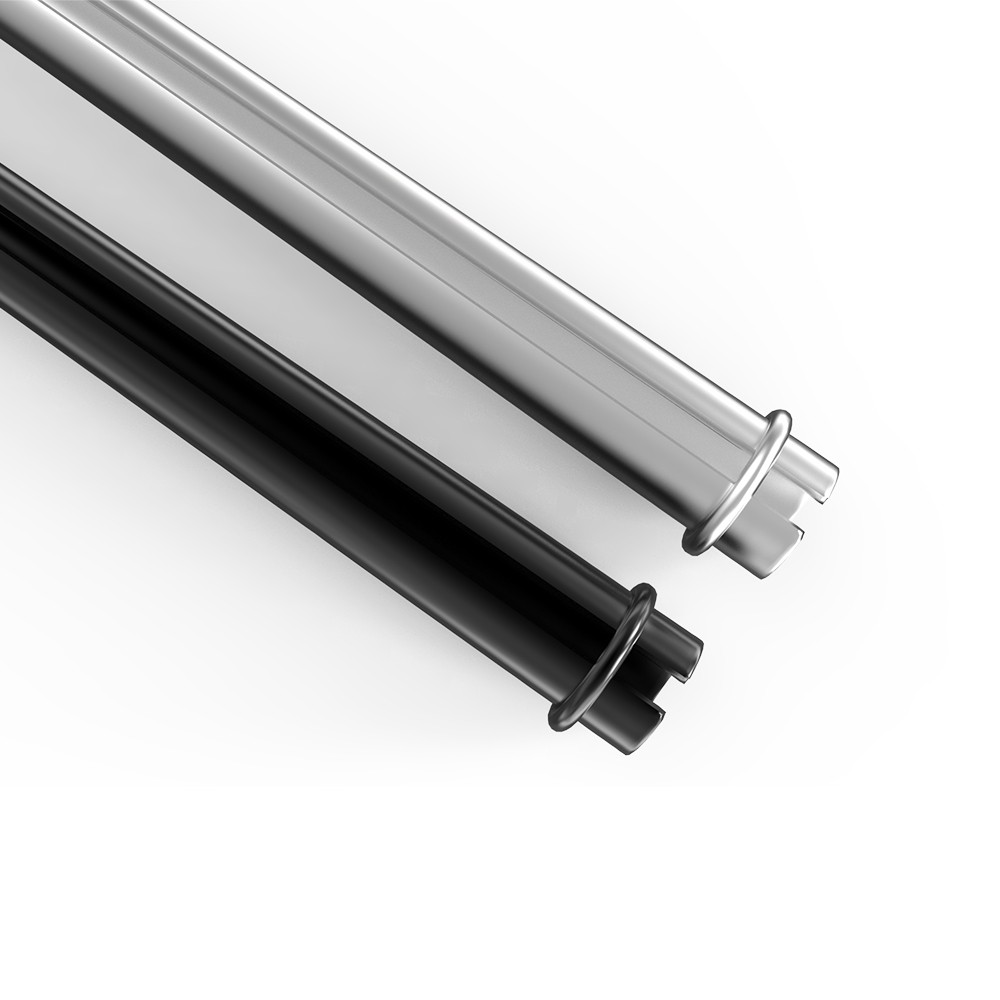

A split set bolt is a type of rock bolt used primarily in underground mining and tunneling to stabilize rock masses. It's a high-strength steel tube with a longitudinal slot along its length and a tapered end for easy insertion into a drill hole.

When the bolt is inserted into a hole slightly smaller than its diameter, it exerts radial pressure against the rock. This pressure generates frictional resistance along the full length of the bolt, effectively anchoring it in place. The bolt's design includes a welded ring flange at the collar, which holds a bearing plate to support loose rock and enhance load distribution.

How Do Split Set Bolts Function in Rock Stabilization?

The functionality of split set bolts lies in their ability to create a continuous and immediate bond with the rock. Here's how they work:

- Insertion into a Drill Hole: The tapered end allows the bolt to be easily inserted into a drill hole that is slightly smaller than the bolt's diameter.

- Radial Pressure Generation: As the tube is driven into the hole, it compresses slightly, causing radial pressure against the rock walls.

- Frictional Resistance: This pressure creates friction between the bolt and the rock, ensuring the bolt remains securely in place.

- Support Enhancement: The addition of a bearing plate at the collar increases the load-bearing capacity, distributing the load and preventing rock movement.

The continuous frictional contact along the bolt's entire length provides consistent support, making split set bolts an effective solution for ground support in various conditions.

Advantages of Using Split Set Bolts in Underground Mining

Utilizing split set bolts in underground mining offers several significant advantages:

- Immediate Support: Provides instant stabilization upon installation, enhancing safety.

- Easy Installation: The bolts are easy to install, requiring simple tools and minimal training.

- Cost-Effective: Reduced labor and equipment costs make them a cost-effective choice.

- Adaptability: Can be used in various rock types and conditions.

- Durability: Made from high-strength steel, they withstand harsh underground environments.

These benefits contribute to improved efficiency and safety in mining operations, making split set bolts a preferred choice for many professionals.

Why Are Friction Bolts Essential for Roof Stability?

The roof of an underground mine is one of the most critical areas requiring support. Friction bolts, such as split set bolts, play a vital role in ensuring the stability of the mining roof:

- Continuous Support: Provides support along the entire length of the bolt, preventing rock falls.

- Load Distribution: The bearing plate helps distribute the load, reducing stress concentrations.

- Adaptability to Movement: The frictional contact allows for slight rock movements without losing support.

- Compatibility with Other Support Systems: Can be used alongside mesh, welded plates, or other supports for enhanced stability.

Implementing friction bolts is a proactive measure to maintain safety and integrity in underground mining environments.

What Makes the 47mm Split Set Bolt Unique?

The 47mm split set bolt is a standard size widely used in the industry. Here's what sets it apart:

- Optimal Diameter: The 47mm diameter strikes a balance between strength and ease of installation.

- High-Strength Steel: Manufactured from high-strength steel for maximum durability.

- Versatility: Suitable for various applications, including mining roof support and tunneling.

- Ease of Installation: The tapered end and appropriate sizing make it easy to install with standard equipment.

This specific size meets many industry needs, providing reliable support in diverse underground conditions.

How to Install Split Set Bolts Effectively?

Proper installation of split set bolts is crucial for achieving optimal performance:

- Drill the Hole: Create a hole with a diameter slightly smaller than the bolt.

- Prepare the Bolt: Ensure the tapered end is clean for easy insertion.

- Insert the Bolt: Drive the bolt into the hole using a specialized installation tool.

- Attach the Bearing Plate: Position the bearing plate against the rock surface as the bolt is driven.

- Ensure Full Engagement: Drive the bolt until the collar is flush with the bearing plate, indicating full engagement.

Following these steps ensures that the bolt generates the necessary frictional resistance and provides effective support.

Split Set Bolts vs. Traditional Rock Bolts: What's the Difference?

Understanding the differences between split set bolts and traditional rock bolts helps in selecting the right ground support:

- Mechanism of Action:

- Split Set Bolts: Rely on frictional resistance along their entire length.

- Traditional Rock Bolts: Often use mechanical anchors or resin/grout to secure the bolt.

- Installation:

- Split Set Bolts: Easy to install, requiring minimal equipment.

- Traditional Rock Bolts: May require more complex installation procedures.

- Cost and Efficiency:

- Split Set Bolts: Cost-effective due to reduced labor and equipment needs.

- Traditional Rock Bolts: May be more expensive due to materials and installation complexity.

Both types have their applications, but split set bolts offer particular advantages in terms of simplicity and immediate support.

Where Are Split Set Bolts Commonly Used in Mining Operations?

Split set bolts are widely used in various mining operations:

- Underground Copper or Gold Mining: Stabilizing the roof of underground copper and gold mining excavations.

- Tunneling Projects: Providing support during the excavation of tunnels.

- Construction Sites: Used in underground construction for stabilizing rock faces.

- Mining Roof Support: Essential for the support of the roof in mining operations.

Their versatility makes them a valuable tool across different sectors requiring rock stabilization.

How Do Split Set Stabilizers Enhance Mining Roof Safety?

As a specific support product, split set stabilizers, also known as friction bolts, enhance safety by:

- Providing Continuous Support: Reducing the risk of rock falls and collapses.

- Easy Integration: Can be combined with mesh, bearing plates, and other supports.

- Adaptable Design: The tapered design allows for use in various rock conditions.

- Durable Materials: Made from high-strength steel to withstand underground conditions.

These features make split set stabilizers an integral part of modern mining safety practices.

What Are the Key Considerations for Selecting Split Set Bolts?

Choosing the right split set bolt involves considering:

- Material Quality: Opt for bolts made from high-strength steel for durability.

- Size and Length: Select the appropriate diameter and length based on the application.

- Coating Options: Hot dip galvanize coatings can enhance corrosion resistance.

- Supplier Credibility: Work with reputable manufacturers who ensure quality and compliance with standards.

- Compatibility: Ensure the bolt fits with other support systems like bearing plates and mesh.

By focusing on these factors, you can select a bolt that meets the specific needs of your project.

What Is the Future of Friction Bolts in Underground Mining?

The future of friction bolts in underground mining looks promising:

- Technological Advancements: Innovations in materials and design will lead to even more effective bolts.

- Ground Support Integration: Combining friction bolts with advanced monitoring systems for real-time feedback.

- Sustainability Focus: Developing eco-friendly materials without compromising strength.

- Global Adoption: Increasing use in underground mines worldwide due to their cost-effectiveness and efficiency.

Continued research and development will enhance the role of friction bolts in ensuring safety and productivity in mining.

Conclusion

Split set bolts are a fundamental component in underground mining and construction, offering a reliable, cost-effective, and easy-to-install solution for rock stabilization. Understanding their function, advantages, and proper installation methods empowers professionals to make informed decisions that enhance safety and efficiency.

By selecting the right products and adhering to best practices, you can ensure the success of your underground projects. Remember, investing in quality ground support is investing in the safety and longevity of your operations.

Key Takeaways:

- Split set bolts provide immediate and continuous support in underground applications.

- Their frictional resistance and easy installation make them a preferred choice.

- 47mm split set bolts are standard for many mining needs.

- Proper installation and selection are crucial for optimal performance.

- The future holds exciting advancements in friction bolt technology.

For more information on related products, check out our Expansion Shell Anchor Bolt and Self-Drilling Hollow Anchor. These technologies complement split set bolts and offer additional solutions for your ground support needs.

Allen's company in China specializes in manufacturing high-quality split set bolts and other drilling tools. With seven production lines and a commitment to excellence, we provide cost-effective solutions to clients worldwide.

Post time: 12 月-17-2024