Drilling into metal might seem daunting, but with the right drill bit, it becomes a breeze. This article is your guide to understanding the world of drill bits, especially when it comes to working with metal studs and other metal materials. We'll explore the types of drill bits, help you choose the best drill bits for metal, and ensure your projects are successful from start to finish. Whether you're a seasoned professional or tackling a home repair, understanding your drill bit options is key. Let's dive in and make metal drilling less of a mystery!

1. What Exactly Are Drill Bits and Why Are They So Important for Metal Drilling?

Imagine trying to make a hole in a wall with just your finger – impossible, right? That's where drill bits come in! A drill bit is a cutting tool used with a drill to create cylindrical holes in materials. Think of it as the pointy "tooth" of your drill that does all the hard work. From hanging pictures at home to massive construction work, drill bits are essential for countless tasks.

But why are they so important, especially when drilling metal? Well, metal is tough stuff! Unlike wood or plastic, metal resists being cut. Using the wrong type of drill bit on metal can lead to frustration, broken bits, and unfinished projects. The right metal drill bits, however, are designed to withstand the heat and pressure of drilling metal, making clean, accurate holes efficiently. For industries like mining and tunneling, where precision and durability are paramount, high-quality drill bits are not just tools; they are critical components that ensure project success and safety. Choosing the right drill bit is the first step in any successful metalworking project.

2. What Type of Drill Bit is Really the Best Drill Bits for Metal Work?

When you walk into a home depot or any hardware store, you might be overwhelmed by the sheer number of drill bits on display. Different types of drill bits are designed for different materials and jobs. So, when it comes to metal drilling, what type of drill bit reigns supreme as the best drill bits for metal?

While there isn't a single "best" for every situation, for general metal drilling, twist drill bits are incredibly versatile and often the best starting point. However, for tougher metals like stainless steel or hardened steel, specialized metal drill bits like cobalt drill bits are often necessary. Then you have titanium-coated bits, which offer enhanced durability for everyday metal tasks. Other specialized bits, like spade drill bits or auger drill bits, which are mainly for wood, are not typically used for metal drilling. Understanding the strengths of each type of drill bit will help you select the most effective tool for your specific metal project. It's all about matching the drill bit to the material and the task at hand.

3. Twist Drill Bits: Are These the Go-To for Metal Drilling?

Twist drill bits are probably the most common type of drill bit you'll encounter. They are easily recognizable by their spiral flutes that run up the shank, resembling a twisted piece of metal – hence the name! These flutes are not just for show; they serve to remove chips from the hole as you drill, preventing clogging and overheating. Twist drill bits are indeed a go-to for many metal drilling tasks because of their versatility and availability.

Most twist drill bits are made from high-speed steel (HSS), which is a good general-purpose material for drilling metal. For even tougher applications, you can find twist drill bits made with cobalt steel or with titanium coatings. Their design makes them effective for creating a wide range of drill holes in various types of metal, from thin sheet metal to thicker plates. For everyday home repair and general metal drilling, a good drill bit set of twist drill bits is an excellent starting point. They are reliable, readily available, and often the best choice for many common metal projects. You can even use them with a drill press for more precise drilling metal.

4. When Should You Reach for Cobalt Drill Bits for Metal Drilling?

When your metal project involves particularly hard materials, like stainless steel, cast iron, or hardened alloys, standard HSS twist drill bits might struggle or wear out quickly. This is where cobalt drill bits shine. Cobalt drill bits are a premium type of drill bit made from high-speed steel that includes cobalt steel in its composition. This cobalt steel addition significantly increases the drill bit's heat resistance and hardness.

Why is heat resistance so important? Drilling metal, especially hard metal, generates a lot of friction and heat. Regular steel drill bits can lose their temper (hardness) at high temperatures, leading to dulling and breakage. Cobalt drill bits, however, maintain their hardness even at elevated temperatures, allowing them to cut through tough metals more effectively and last longer. If you find yourself needing to drill hardened steel or drill bits for stainless steel, cobalt drill bits are often the best choice. While they are more expensive than standard HSS bits, their superior performance and longevity in demanding metal drilling applications make them a worthwhile investment, especially for professional use or frequent work with hard metals. For tasks requiring extra strength and durability, cobalt bits are the answer.

5. Titanium Drill Bits: Hype or Help for Tough Metal Drilling Jobs?

You've likely seen titanium drill bits prominently displayed, often marketed for their enhanced performance. But are titanium drill bits truly the upgrade they claim to be, especially for tough metal drilling? It's important to understand that most titanium drill bits are not actually made of solid titanium. Instead, they are typically HSS drill bits with a thin titanium nitride coating. This coating is harder than HSS and provides several benefits.

The titanium coating on titanium-coated bits reduces friction and heat buildup, which can extend the life of the drill bit compared to uncoated HSS bits, particularly when drilling metal. They are also more resistant to wear and tear, making them a step up from basic HSS bits for general-purpose metal drilling. However, it's crucial to note that the coating is just a surface treatment. Once the coating wears off, you are essentially left with a standard HSS drill bit. For truly demanding and prolonged metal drilling in very hard metals, solid cobalt drill bits generally offer superior performance and longevity because their hardness is throughout the entire bit you need, not just a coating. Titanium bits are a good middle-ground – better than basic HSS, but not as robust as cobalt bits for the toughest jobs. They are well-suited for a variety of metal drilling applications and home repair tasks, offering a balance of performance and cost.

6. Beyond the Basics: Are There Other Types of Drill Bits for Specialized Metal Tasks?

While twist drill bits, cobalt drill bits, and titanium drill bits cover a wide range of metal drilling needs, the world of drill bits is vast, and there are other specialized types designed for specific metalworking tasks, though some are more commonly used for wood or other materials.

-

Spade Drill Bits (Paddle Bits): Primarily for wood, spade drill bits are flat with a pointed tip and two cutting edges. They are designed to create large diameter holes quickly in wood but are generally not suitable for metal drilling due to their design and lack of chip removal efficiency in metal.

-

Auger Drill Bits: Also mostly for wood, auger drill bits have a screw-like tip that pulls the bit into the wood, making them efficient for deep holes in wood. They are not designed for metal and would be ineffective and likely damaged if used for metal drilling.

-

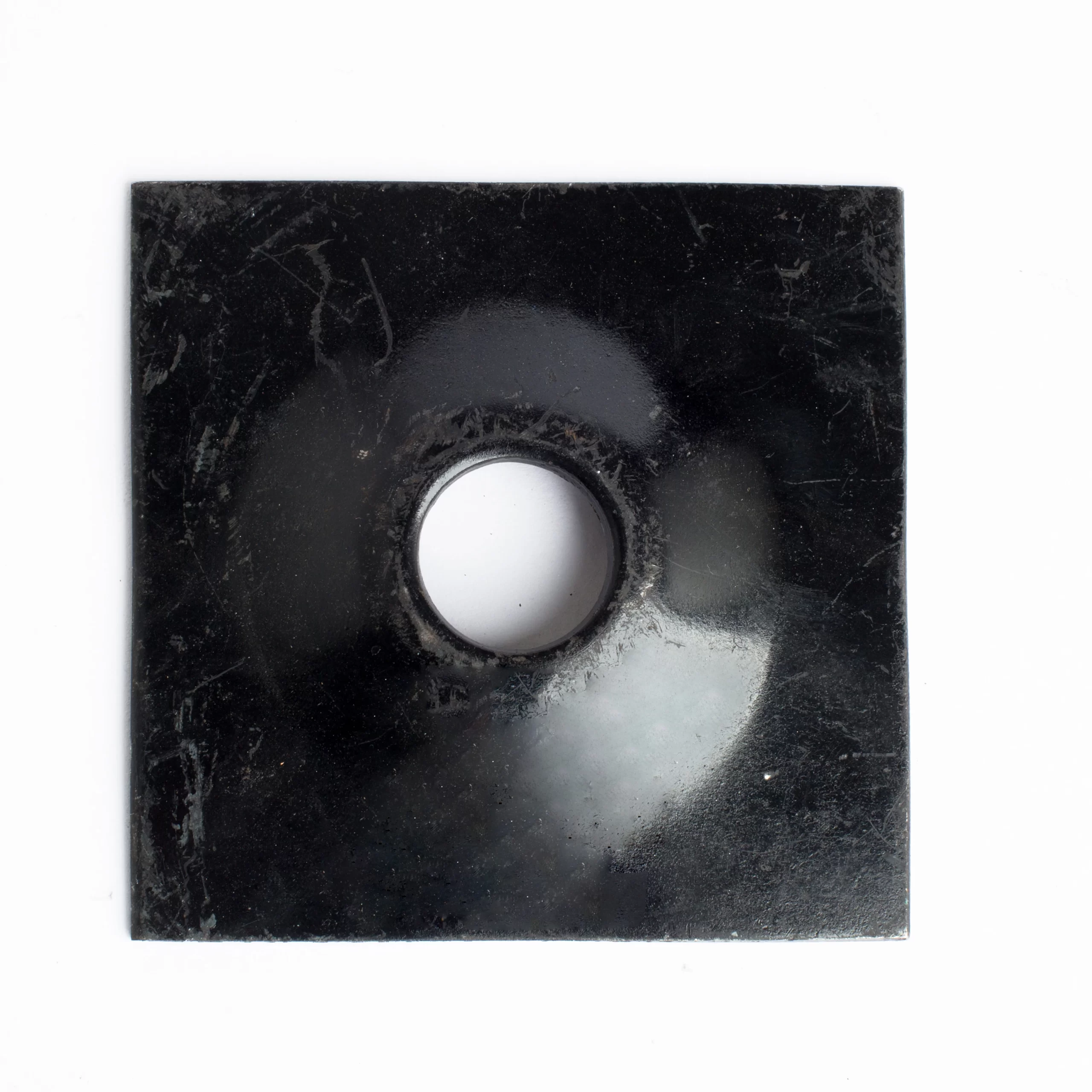

Coring Drill Bits (Annular Cutters): These specialized bits are designed to cut a hole by removing a core of material, rather than turning the entire diameter into chips. While less common in general DIY, coring drill bits are used in industrial metalworking for creating large diameter holes in sheet metal and thicker metal plates efficiently. They are different from standard drill bits and require specialized drill press or magnetic drills.

-

Countersink Bits: Countersink bits are designed to create a conical depression around the top of a drill hole. This allows screw heads to sit flush with or below the surface of the material. Countersink bits are very useful in metalworking to create clean finishes for screw and fastener applications. They can be used after drilling pilot holes with a standard metal drill bit.

-

Installer Bits (Bellhanger Bits): These are long, slender twist drill bits with a hole drilled through the flute near the tip. While sometimes used in electrical and telecommunications work, they are not specifically designed for heavy metal drilling. Their length can make them prone to bending or breaking when used on hard metals.

While some types of drill bits, like spade drill bits and auger drill bits, are largely irrelevant for metal drilling, others like coring drill bits and countersink bits serve very specific and valuable purposes in metalworking. Understanding these specialized bits come in handy for advanced metal projects.

7. Drilling Metal Studs: What Drill Bit Do You Need for Steel Studs?

If you're working on interior walls or framing, you might encounter metal studs, also known as steel studs. These are increasingly common alternatives to wood studs. Drilling into metal studs requires a different approach than drilling into wood. The good news is that metal studs are typically made of relatively thin gauge steel, making them easier to drill than thicker metal plates.

For drilling metal studs, standard twist drill bits made of HSS are usually sufficient. A drill bit set containing various sizes of HSS twist drill bits will be very useful. Titanium-coated bits can offer a bit more longevity, especially if you have many holes to drill. Cobalt drill bits, while excellent for harder metals, are generally overkill for metal studs and might be unnecessarily expensive for this application.

When drilling metal studs, it's important to use the correct size drill bit for your screw or fastener. Often, self-tapping drywall screws are used with metal studs, and you may not even need a pilot hole for very thin gauge studs. However, for thicker steel studs or for using bolts or rivets, drilling pilot holes is recommended. Start with a smaller drill bit to create a pilot hole, then enlarge it if necessary. Using a drill press is not usually necessary for metal studs in typical construction, a hand-held drill will suffice. The key is to use a sharp HSS twist drill bit of the appropriate size and apply steady pressure while drilling slowly to prevent overheating the bit.

8. Are Drill Bit Sets a Smart Buy, or Should You Pick Metal Drill Bits Individually?

Considering purchasing drill bits? You'll often find them sold individually or in drill bit sets. For someone like Mark Davis, a B2B buyer focused on cost-effectiveness and quality, deciding between drill bit sets and individual metal drill bits is an important consideration.

Drill bit sets offer several advantages:

- Variety: Sets typically include a range of drill bit sizes, which is useful for tackling different projects and drilling pilot holes of varying sizes.

- Convenience: Having a drill bit set means you likely have the bit you need on hand without needing to make separate purchases each time.

- Storage: Sets often come in organized cases, making it easier to store and locate your drill bits.

- Initial Cost Savings: Buying a drill bit set is often cheaper than purchasing the same number of drill bits individually.

However, there are also potential downsides to drill bit sets:

- Quality Variation: Lower-priced bit sets may contain drill bits of lower quality that dull quickly or break easily. You might end up with many bits made of inferior material.

- Unnecessary Bits: You might get bits come in a set that you rarely or never use, adding to the overall cost without providing practical value. For example, a set might include many wood or ceramics drill bits if your primary need is metal drilling.

- Replacement Costs: If you frequently use a particular size drill bit, it will wear out faster in a set. Replacing just that one drill bit might be difficult, forcing you to buy a new set or individual bits anyway.

For B2B buyers like Mark Davis, who prioritizes quality and value, it's often wise to invest in a smaller drill bit set of good quality HSS or titanium-coated twist drill bits for common sizes. Then, for specialized metal drilling needs like stainless steel or hardened steel, purchase high-quality cobalt drill bits individually as needed. This approach balances cost-effectiveness with ensuring you have reliable metal drill bits for various tasks without ending up with a set didn't come with the quality or specific bits for metal drilling you truly need. Inspect drill bits in any set carefully for quality before bulk purchase.

9. How to Choose the Best Drill Bits for Metal: A Step-by-Step Guide

Choosing the best drill bits for metal doesn't have to be complicated. Here's a step-by-step guide, keeping Mark Davis's B2B procurement needs in mind:

-

Identify the Metal Type: What kind of metal will you be drilling? Mild steel, steel studs, stainless steel, hardened steel, cast iron, or aluminum? Harder metals require more robust drill bits like cobalt drill bits. Softer metals can often be drilled with HSS or titanium-coated bits.

-

Determine Hole Size and Depth: What diameter and depth of drill holes do you need? Smaller holes in thin metal might be fine with standard jobber length bits, while deeper or larger holes may require longer or specialized bits.

-

Choose the Right Drill Bit Material and Coating:

- HSS (High-Speed Steel): Good for general-purpose metal drilling, metal studs, and softer metals. Cost-effective for bulk purchases.

- Titanium-Coated HSS: Offers improved wear resistance and heat reduction compared to HSS, suitable for moderate metal drilling.

- Cobalt Steel: Often the best choice for hard metals like stainless steel, hardened steel, and cast iron. Provides superior heat resistance and durability but is more expensive.

-

Select the Correct Drill Bit Type: For most metal drilling, twist drill bits are the workhorse. Consider countersink bits for creating flush screw holes and coring drill bits for large diameter holes in industrial applications. Spade drill bit and auger drill bit are not for metal.

-

Consider Your Drill: Are you using a hand-held drill or a drill press? For precise and consistent drilling metal, a drill press is ideal, especially for larger holes or harder metals. For metal studs and lighter tasks, a hand-held drill is usually sufficient. For very hard materials, a slower speed and more pressure might be needed; sometimes a hammer drill or rotary hammer (though less common for metal) might be considered for very specific applications.

-

Evaluate Drill Bit Sets vs. Individual Bits: For B2B, a combination approach is often best. Purchase quality drill bit sets of common HSS or titanium-coated sizes for general use and then buy cobalt drill bits individually for specialized hard metal applications.

-

Check for Certifications and Supplier Reliability: As Mark Davis knows, quality and certification (like ISO standards) are crucial. Source drill bits from reputable suppliers, such as factories in China with proven quality control. Consider requesting samples and conducting quality inspections.

-

Consider Cost and Value: Balance the initial cost with the long-term value. Cheaper bit sets might seem appealing, but if they wear out quickly or break easily, they can end up costing more in the long run due to replacements and project delays. Invest in quality metal drill bits that are reliable and durable.

By following these steps, Mark Davis and other B2B buyers can make informed decisions and choose the best drill bits for metal that meet their quality, performance, and budget requirements.

10. Keeping Your Metal Drill Bits Sharp: Maintenance Tips for Long Life

Even the best drill bits for metal will eventually dull with use. However, proper maintenance can significantly extend their lifespan and maintain their efficient drilling performance. Here are some key tips to keep your metal drill bits in top shape:

-

Cooling and Lubrication: Drilling metal generates heat, which is a drill bit's enemy. Use cutting fluid or coolant when drilling metal, especially harder metals. This reduces friction and heat, preventing the bit from overheating and losing its temper. Even water can help in a pinch. Drilling slowly also helps reduce heat buildup.

-

Proper Speed and Pressure: Use the correct drilling speed for the type of metal and drill bit size. Generally, slower speeds are better for harder metals and larger diameter drill bits. Apply consistent, firm pressure, but don't force the drill bit. Let the cutting edges do the work. Too much pressure can cause the bit to overheat and break.

-

Regular Cleaning: After each use, clean your drill bits. Metal chips and debris can stick to the flutes and hinder performance. A wire brush can be used to remove debris.

-

Sharpening (When Possible): HSS and cobalt drill bits can be sharpened, although it requires skill and the right tools (like a drill bit sharpener or a grinding wheel). Titanium-coated bits should ideally be sharpened carefully to avoid removing the coating near the cutting edge. For B2B, it might be more cost-effective to replace dull bits, especially if using lower-cost HSS bits. However, sharpening premium cobalt drill bits can be worthwhile.

-

Proper Storage: Store your drill bits in an organized manner, preferably in a drill bit set case or a drill bit holder. This protects the cutting edges from damage and makes it easy to find the bit you need. Avoid tossing drill bits loosely in a toolbox where they can bang against other tools and dull.

-

Regular Inspection: Inspect drill bits before and after each use. Look for signs of wear, dulling, chipping, or damage. Replace drill bits that are damaged or excessively worn to maintain drilling efficiency and prevent breakage during projects.

By following these maintenance tips, you can maximize the life of your metal drill bits, ensuring they remain effective and reliable for all your metal drilling projects, contributing to cost savings and efficient construction work or other applications.

Key Takeaways for Choosing the Best Drill Bits for Metal:

- Twist drill bits are versatile for general metal work, especially HSS and titanium-coated.

- Cobalt drill bits are essential for hard metals like stainless steel and hardened steel due to superior heat resistance.

- Titanium-coated bits offer improved wear resistance over standard HSS but are not as strong as solid cobalt bits for very hard metals.

- For metal studs, HSS or titanium-coated twist drill bits are usually sufficient.

- Drill bit sets can be cost-effective for variety, but consider quality and whether you need all the included sizes.

- Proper cooling, speed, pressure, and maintenance are crucial for extending drill bit life.

- Choose drill bits based on the type of metal, hole size, and application for optimal performance and cost-effectiveness.

By understanding these factors, you can confidently select the best drill bits for metal for any project, ensuring efficient and successful results every time! Remember to always prioritize safety and use appropriate personal protective equipment when drilling metal.

Internal Links:

- Explore our range of high-quality Self-drilling Hollow Anchors for your heavy-duty construction needs.

- For demanding rock conditions, consider our durable Split Rock Friction Anchors for reliable support.

- Ensure secure connections with our robust Couplings designed for demanding applications.

- Optimize your drilling setup with our precision-engineered Shank Adapters.

- Discover our comprehensive selection of Rock Drilling Bits to find the perfect match for your drilling requirements.

Post time: 2 月-04-2025