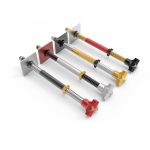

Self-drilling Hollow Anchor

Product Introduction

Compared with other anchors, the advantage of self-drilling anchors is that they are good at work in complex ground conditions where drilling is difficult (E.g. fractured, clay, loose, narrow and broken geological conditions). It provides comprehensive anchoring solutions for the excavation and engineering support industries.

The interior of the self-drilling hollow anchor is hollow and has no physical substance. The air and water inside can move freely during the drilling process and wash away particles. There are continuous threads on the outside that can be cut off at any place. Also comes with drill bit for drilling holes. Due to its own characteristics, self-drilling hollow anchors have a wide range of applications. They can be used for tunnel stabilization, dams and slopes, avalanche safety protection, as well as pre-support projects, radial support projects, edge skin stabilization, foundation support projects, and roadways. Support engineering and other rock support work. Because the anchor itself is an advanced system, the installation steps are simple and the operation is easy. It can work under complex foundations, such as weak rocks, loose soil, weathered layer, gravel layer and other broken address conditions, and can drill simultaneously. Holes, grouting, and anchoring greatly improve work efficiency. Anchors are popular all over the world due to their wide range of uses and applications in many fields.

Product Advantages

1.Drilling, anchoring and grouting simultaneously (grout can effectively fill cracks.)

2.Simple installation and easy operation. Greatly improved work efficiency.

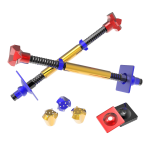

3.Select drill bits according to different ground conditions.

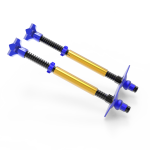

4.Can be elongated by using couplers.

5.Suitable for broken geological conditions.

6.Because the outside is threaded, it has higher bonding stress than smooth steel pipes.

7.It has many uses and is widely used, including tunnel stabilization and reinforcement, dam slopes, avalanche safety protection, support engineering, etc.

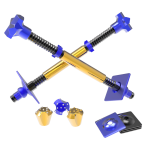

Installation Process

Self-drilling bolts are usually installed using rotary impact drilling.

This technology allows for high installation rates, good directional stability, and helps consolidate the grout within the borehole.

1.Connect the alloy drill bit and anchor rod to one end, connect the drill sleeve and adapter to the other end, and then connect the drill rig or hand-held drill rig.

Then start drilling, adding cooling water while drilling. (If you want to lengthen the anchor rod, you can connect the coupling and then drill holes)

2.Remove the drill bit, insert the grouting stopper into the rod, and insert it into the hole to prepare for grouting.

3.Connect the grouting joint and the anchor end, and connect the other end of the grouting machine.

4.Start grouting. When the grouting is full and reaches the design value, turn off the power.

The grouting pressure is determined based on the design parameters and grouting machine performance.

5.Install the base plate and nuts, and tighten the nuts.

Product Application